In order to improve the automation effect of liquid sanitary napkin machine, effective design, highlighting the operational advantages to meet the development requirements of various industries. However, in the design process, it is often affected by a series of external factors that increase the possibility of safety hazards in the design. In order to ensure the smooth implementation of the design, this paper mainly analyzes the practical significance of liquid sanitary napkin machine safety control management, and proposes a series of safety management measures.

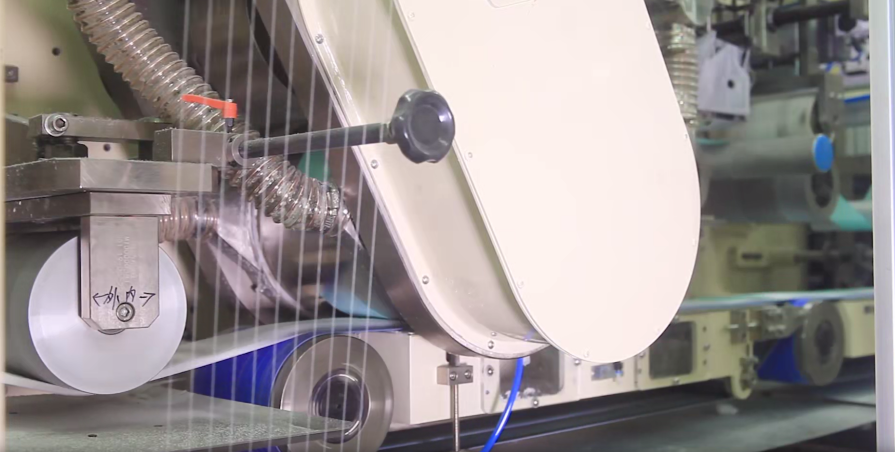

For liquid sanitary napkin machine, its overall structure is more complex. This has caused frequent problems in the design process. In order to improve this situation, it is necessary to plan a reasonable and effective design model from the perspective of the overall structure of the liquid sanitary napkin machine to avoid design problems. At the same time, the safety control management of the design of the liquid sanitary napkin machine, effective assessment of the possible safety risks in the design process of the liquid sanitary napkin machine, and the development of effective improvement measures in combination with various safety risks. Make the practical value of mechanical automation equipment to give full play to improve the design level.

Fully consider the functional requirements of mechanical automation equipment. In order to strengthen the effect of safety control management in the design of liquid sanitary napkin machine, a reasonable safety control management model should be developed to narrow the gap between safety control management and design requirements, and further improve the goal of safety control management of mechanical automation equipment design.

Application of a series of new technical means. For safety control management, a series of advanced technical means can also be applied to ensure that safety control management in a variety of advanced technology and design in a state of interconnection, and constantly improve the design of safety control management of advanced technical means, so as to provide a broader space for the development of mechanical automation equipment. For the designers, the personnel concerned are required to take the initiative to learn various advanced technical means and effectively master the operation methods and operation skills.

Improve the efficiency of safety control. Generally speaking, with the support of safety control management mode, the design can be effectively managed, the operating information parameters can be optimized when necessary, the risks in the design and operation process can be avoided, and the safety function requirements of the LIQUID SANITARY NAPKIN MACHINE can be improved comprehensively. Therefore, it is necessary to enhance the design of safety control management by improving the efficiency of safety control, improving the unreasonable places in the corresponding management mode, and thus promoting the smooth development of the design.

Manifesting the degree of safety and reliability of equipment. With the support of safety control management, the failures that occur during the long-term operation of the liquid sanitary napkin machine should be optimally adjusted to control the influence of various external factors on the design effect.

In summary, the design of the liquid sanitary napkin machine plays a very important role in maintaining the operational effectiveness of mechanical automation equipment. Therefore, in the later operation process, it is necessary to ensure the rationality of the design and avoid quality problems. In order to reduce the probability of safety risks in the design process, effective safety control management should also be implemented.

Comment(0)

You can comment after

SIGN IN