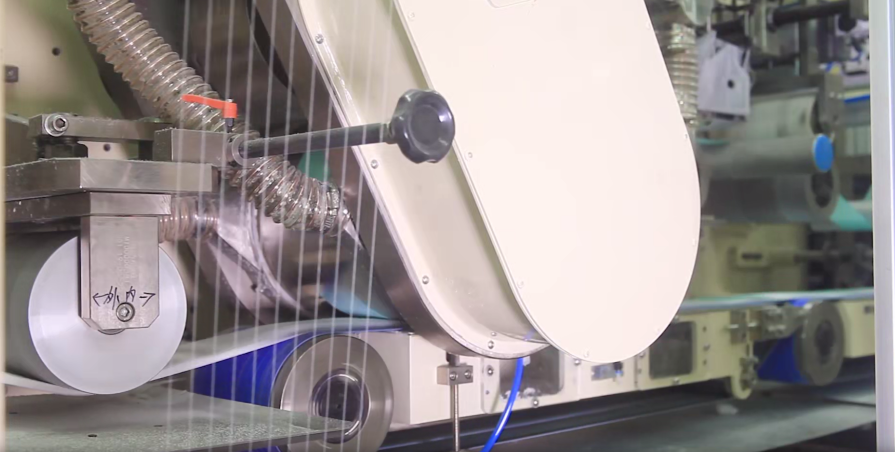

At present, one of the key tasks that companies need to focus on is how to run sanitary pads equipment stably to achieve efficient production of products. In view of this, the article through the meaning of improving sanitary pads equipment high performance to start interpretation, combined with the future development of positioning, so as to promote the industry to achieve mechanization and provide certain technical support.

(1)Guarantee production safety

The prerequisite basis for enhancing the execution of action is safety. Production is an engineering project with a complex working environment and high requirements for equipment safety performance. And whether sanitary pads equipment internal structure and functional system is complete, to a large extent, determines the safety of the production process. Therefore, good equipment management is actually to provide certain power support to ensure operational safety. Especially for sanitary pads machine, its operation management, to promote its high efficiency for system operation, and effectively reduce the risk of accidents hidden danger.

(2) Guaranteeing product quality

In the new era of product processing field, sanitary pads machine occupies an important part, but also is the key element to determine the quality of the product. And do a good job of sanitary pads equipment daily management, functional maintenance and risk overhaul, can ensure the smooth development of the production operation processes, further optimize the production environment, improve the overall quality of product processing, to ensure that the product qualification rate up to standard. Effectively avoid the cost waste caused by product processing irregularities.

Enterprise development

Along with the sales market environment market competition trend is becoming increasingly tense, the company according to the standardized sanitary pads equipment management method, can reasonably improve the current operation of the natural environment, improve the overall work efficiency of product production and processing, and then all-round enhance the company's production strength, for its natural environment in the sales market to obtain a beneficial development trend status and produce a certain driving force Support point, in addition to the company can complete a deep and smooth development trend to show a full range of equipment carrier support point. It can be seen that the standardization of equipment management is of great significance for production and processing, business operation or market macro development, which is the main reason why companies need to strengthen equipment management and they must implement management work.

In summary, good equipment management is of great practical significance for the overall improvement of chemical production efficiency and ensuring product quality. Therefore, in the new production environment, enterprises need to pay great attention to the management of sanitary pads equipment.

Comment(0)

You can comment after

SIGN IN