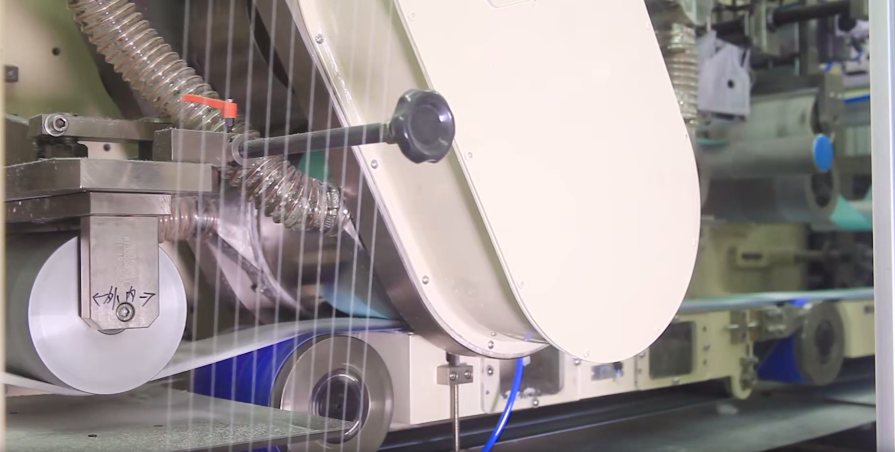

Dry mesh sanitary napkin equipment processing error is an important basis for reflecting the quality of the workpiece. Once the error exceeds the allowable range of error, the workpiece will no longer have the value of use, which not only causes economic loss, but also wastes the valuable time of personnel. However, in order to effectively avoid or reduce errors, we should find out the specific causes of errors and take targeted solutions to solve them. In order to improve the processing quality of the workpiece, this paper also mainly analyzes and discusses the causes of errors, and proposes some solutions for personnel reference.

Geometric error.

The processing error of different processing parties varies depending on the processing method. In the dry mesh sanitary napkin equipment processing bore and outer circle, the spindle radial rotation error through the production can also cause the cylindricity and roundness error of the workpiece, but in general is the processing of the workpiece end face will not have an impact. Although it has a critical impact on the flatness and perpendicularity of the machined end face, spindle axial rotation error usually has little effect on the machining of bores and external circles.

Tooling, fixtures and errors in the positioning datum.

According to the basic dimensions, the positioning elements on the fixture cannot be manufactured with absolute accuracy, and their actual dimensions (or positions) are allowed to vary within the individually specified tolerances. But if the positioning error changes beyond the tolerance allowed range, it will cause the workpiece and fixture gap exists, and in the dry mesh sanitary napkin mechanical processing process to produce a large amount of position change, which leads to dry mesh sanitary napkin machinery processing parts error.

The process system error generated by the force deformation.

dry mesh sanitary napkin equipment processing process due to the process system error arising from force deformation is mainly determined by the workpiece stiffness, tool stiffness and machine tool component stiffness three factors. The stiffness of various parts also has a certain influence on the processing error of mechanical parts, because it has many complex internal parts.

The error is directly reduced or eliminated.

Improve the accuracy of machine tools, fixtures, gauges and tools used in the processing of the workpiece, control the process system, etc. In order to improve the processing accuracy, after determining the main factors of processing errors, the law should be implemented according to the specific situation. For the processing of precision parts, the accuracy used should be improved as much as possible and the deformation during processing should be controlled. For the processing of low stiffness parts, the main purpose is to reduce the force deformation of the workpiece, and for the processing of forming parts, the main purpose is to reduce the shape error of forming tools and the installation error of props.

The error method of compensation or offset.

Error compensation method, is to offset the original error in the original process system caused by a new error. Error offset method is to use one original error to offset another error, try to make the two equal and reverse. There is no essential difference between these two methods, which are collectively referred to as error compensation in production.

Error transfer method.

Under certain conditions, the original error of the process system can be transferred to the non-significant direction, without affecting the machining accuracy or error. In this way, higher machining accuracy can be obtained without reducing the original error. It is possible to use dry mesh sanitary napkin equipment of general accuracy and process it by the method of error transfer.

In conclusion, excessive errors can not only affect the machining accuracy and quality of the workpiece, but usually also cause the scrapping of the workpiece, but for dry mesh sanitary napkin equipment processing, errors are difficult to avoid. Therefore, in order to control the errors effectively, it is necessary to find out the specific causes of errors and develop different solutions according to different causes.

Comment(0)

You can comment after

SIGN IN