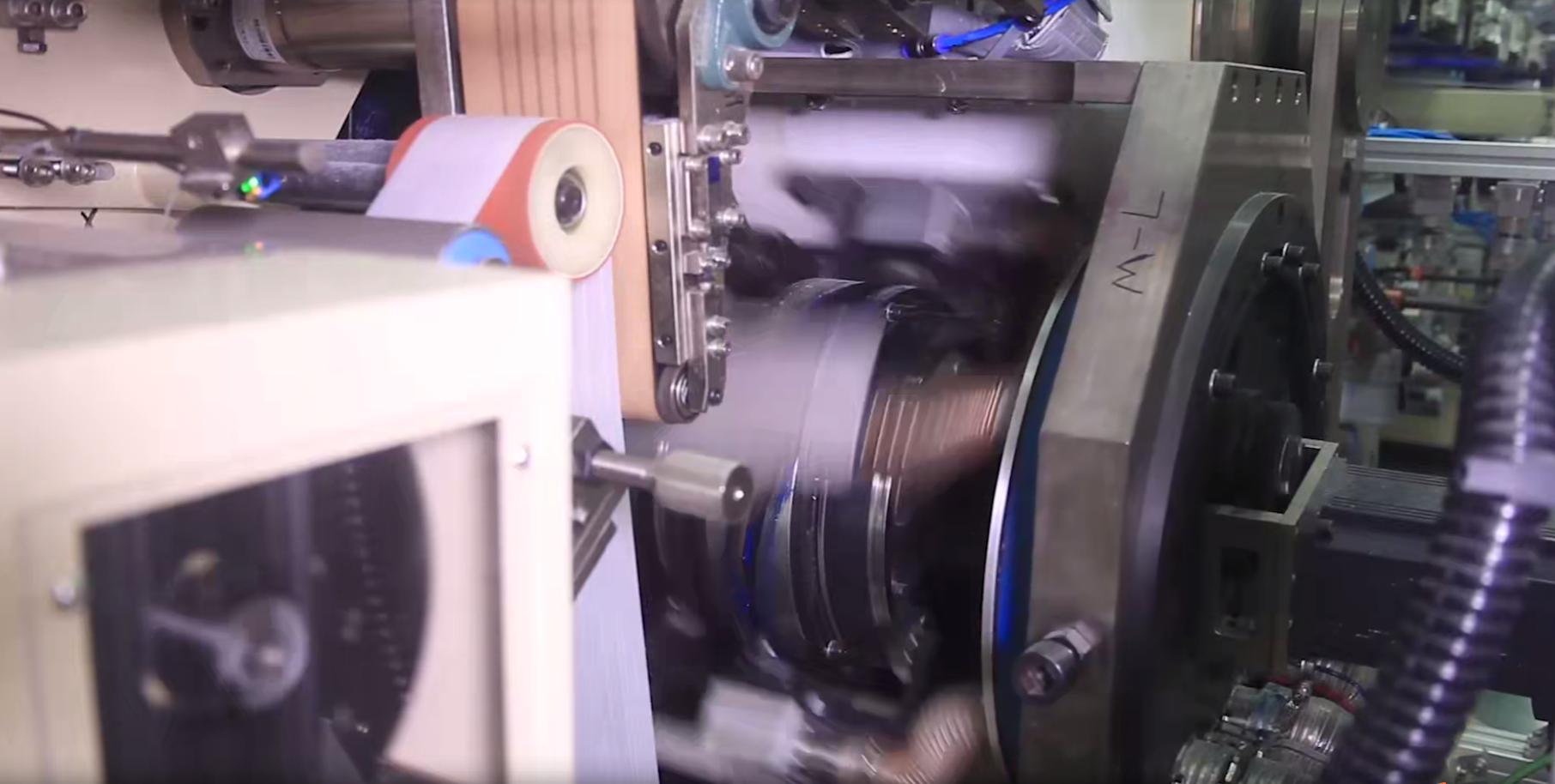

Part processing metric directly affects the performance and life of the parts. In the processing of the impact of parts processing accuracy is very many factors, affecting the overnight sanitary napkin machine processing accuracy of many factors, in order to improve the accuracy, we must start from its impact factors. This paper analyzes the specific measures to improve the accuracy, starting from the analysis of factors.

(1) Minimize the original error method

As we said, errors are inevitable, we can only reduce. Improve the accuracy of fixtures, measuring tools and tools themselves, improve the geometric accuracy of the part processing machine tools, control the stress of the process system, thermal deformation, tool wear, deformation caused by internal stress, measurement errors, etc., mainly from the following aspects: improve the geometric accuracy of the part processing machine tools. The above method is a direct control of the original error, but also the overnight sanitary napkin machine production is widely used in the method.

(2) Compensation of the original error method

Compensation of the original error can minimize the impact of the error on the machining accuracy of the parts, when certain external factors can not directly control the original error. The so-called error compensation method, that is, artificially create a new error to compensate or offset the original error inherent in the original process system can not be changed or avoided, thereby reducing machining errors and improving machining accuracy. When the original error is negative, the artificial error takes a positive value; when the original error is positive, the artificial error takes a negative value.

(3) Transfer of the original error method

Error transfer method, generally for the key characteristics, when the original error directly lead to the key characteristics of the error, will lead to the night sanitary napkin mechanical parts failed or even scrap, transfer the original error method is to transfer the error to non-key characteristics by transferring the original error, the measures that can be taken mainly include: transfer geometric error, transfer thermal deformation, transfer force deformation, etc..

If theovernight sanitary napkin machine processing process to try to transfer it to the direction of non-sensitive processing errors, it can greatly improve processing accuracy. Such as when the machine tool accuracy can not meet the requirements of parts processing, often deliberately require machine tool accuracy, but from the processing process, fixtures and other components to find ways to create conditions so that the overnight sanitary napkin equipment geometric errors are transferred to aspects that do not affect the processing accuracy of the workpiece.

(1) Evenly divide or homogenize the original error method

Dividing or homogenizing some of the original error is to address the existence of the original error in the processing process, which usually leads to the corresponding process of overnight sanitary napkin machine processing error, when the material properties of the processed workpiece changes, or the previous process of processing technology changes, the original error changes more, leading to changes in the next process error.

(2) In-situ processing method

In-place processing method in the night sanitary napkin mechanical components, parts processing is often used as an effective measure to ensure the accuracy of parts processing. In the process of processing and assembly, involving parts or parts between the accuracy of the problem is very complex, so sometimes it is impossible to improve the accuracy of the parts themselves alone, and can easily solve the seemingly very difficult accuracy problems.

In the machining of night sanitary napkins, errors are not the same as mistakes, but they can be minimized. Specific measures to improve machining accuracy have been analyzed, resulting in improved machining accuracy.

Comment(0)

You can comment after

SIGN IN