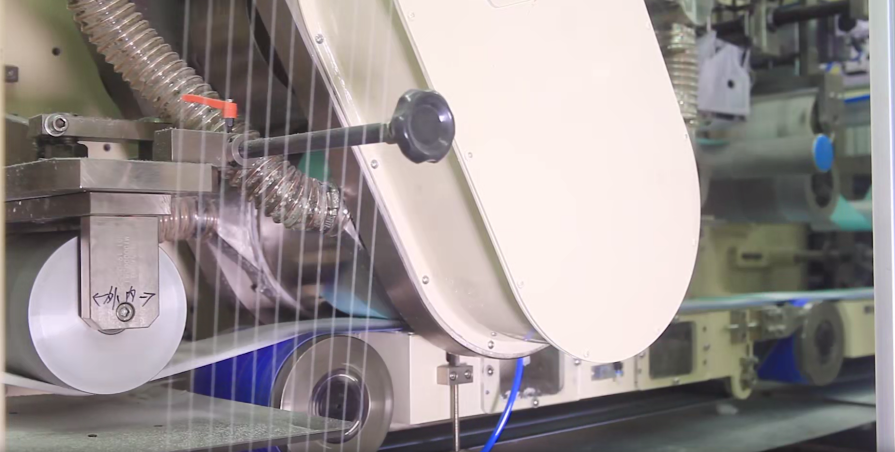

Mechanical processing is a very important part of the industrial development process. The precision of the parts is the core indicator of the quality of the parts. In the process of machining, there are many factors that affect the precision of parts processing, resulting in unqualified product quality and bringing unnecessary trouble to our production life. This paper specifically introduces the reasons affecting the precision of feminine sanitary napkin equipment to affect the precision of machining as the entry point.

(1) Processing errors caused by the process system

The force or heating will affect the processing accuracy of the process system. In the process of system processing, gravity and inertia forces will lead to system deformation, and the parts processed under the deformation system will lead to processing errors; in addition, due to the uneven surface hardness of the blank, the reverse force of the cutting force is not uniform due to different processing hardness, and the location of the force point may drift, affecting the shape accuracy of the workpiece.

In the processing of feminine sanitary napkin equipment, the process system will inevitably be affected by other heat sources and deformation, so that the precision of feminine hygiene napkin machining is affected. The heat sources that cause the deformation of the process system are mainly three: First, the workpiece will become hot during processing for its own or external reasons, resulting in processing errors; Second, the process system is a long-term operation of the formation of heat sources, each heat source is not uniform, affecting the accuracy of the processed parts; Third, the feminine sanitary napkin machine processing tools, which may damage the tools, affecting processing accuracy.

(2) The geometric error caused by the process system

The so-called feminine sanitary napkin equipment geometric errors are reflected in four areas: processing principles, machine tools, tools, and adjustments. In order to avoid geometric errors caused by the process system, it is necessary to improve the accuracy of the processing principle, the stability of the machine tool operation, the correctness of the tool installation, the accuracy of the tool cutting and the correct process adjustment.

(1) Mechanical processing accuracy positioning errors

There are corresponding part diagrams to confirm the design datum of the surface dimensions and position of the parts. In other words, the benchmark of the parts diagram directly affects the production and processing of feminine sanitary napkin equipment. Generally speaking, the design datum is consistent with the process datum. Before machining, several key machining characteristics will be selected as benchmarks, and machining errors will occur if their positioning benchmarks do not agree with the design benchmarks.

(2) The error caused by the distribution of internal stress

The feminine sanitary napkin equipment workpiece will generate internal stresses during machining, even if it is in a force-free state. This internal stress will make the energy level state of the metal abnormal, so that it has a tendency to transform to low energy level, thus seeking the stability of the workpiece itself. The action triggered by this tendency can cause deformation of the workpiece and thus affect its accuracy. Internal stresses in the workpiece mainly occur in processes with large temperature variations, such as hot working or cold straightening. Some slender workpieces tend to bend due to the uneven length and surface shape of the workpiece.

Through the specific analysis of the causes, this paper analyzes the reasons affecting the machining accuracy, so as to improve the machining accuracy of feminine sanitary napkin equipment.

Comment(0)

You can comment after

SIGN IN