Under the influence of the COVID-19, masks are widely used in people's daily life. Meltblown non woven fabric, as one of the important raw materials of medical masks, has also attracted more and more attention. This paper puts forward some suggestions for the future development of meltblown non woven industry.

Strengthen the research and development of high-performance, recyclable and degradable products / materials, actively develop the application of polyethylene terephthalate (PET), polyethylene (PE), nylon-6 (PA6), polylactic acid (PLA), phenylethylamine (PEA), elastic polyurethane (elastic PU) and polytrifluoroethylene (PCTFE) in the field of meltblown non woven fabric, and accelerate the innovative practice of nano melt blown fiber in filter materials. Accurately grasp the trend of mixing and compounding in the development of melt blown technology, encourage leading enterprises in the industry to accelerate the upgrading and mutual penetration of various processes, increase R & D investment in high efficiency, specialization, greening and intelligence, explore advanced design concepts and high-end technology applications, and improve the core competitiveness of the industry.

Meltblown non woven fabric industry after a special period of explosive growth, the problem of overproduction is very prominent. Therefore, it is necessary to innovate the support methods of policies, and connect the supply and demand channels to reduce the business risks of the company by improving the construction of raw material system, technical equipment system, product testing system and emergency material reserve system. Make full use of the insurance compensation system for the first batch of new materials and the policies for the construction of key platforms, explore support methods to reduce the risks of enterprise technological innovation and process research and development, and make full use of the Industrial Development Fund for industrial transformation and upgrading to make up for the lack of funds for the company's industrial transformation.

Market fluctuations have a great impact on the healthy and efficient operation of meltblown non woven fabric enterprises, and the transformation of industrial diversification is imminent. On the one hand, the melt blown cloth industry should gradually improve product functions, eliminate backward production capacity and technical processes, and increase the transformation and penetration of high value-added fields such as the automotive industry, high-end medical and health products and new industrial products through the introduction of new technologies and processes. Aim at the field of deep processing of products, form a functional, differentiated and diversified product application system, and promote industrial upgrading from the aspects of accelerating the breakthrough of key technologies, innovating market applications, and improving market competitiveness.

Give full play to the role of the alliance, take the industry association / alliance as the starting point, build a talent chain around the industrial chain, and strengthen the accumulation and reserve of professional talents. Give full play to the link advantages of the alliance, develop key common technologies closely around the meltblown non woven fabric industrial chain, and promote the collaborative innovation of companies, colleges and universities, and scientific research institutes. Cultivate local technical talents, expand the high-end talent team by using the "introduced" method, support companies upstream and downstream of the industrial chain to give full play to their talent advantages in various fields, and carry out joint restructuring and group development guided by the market.

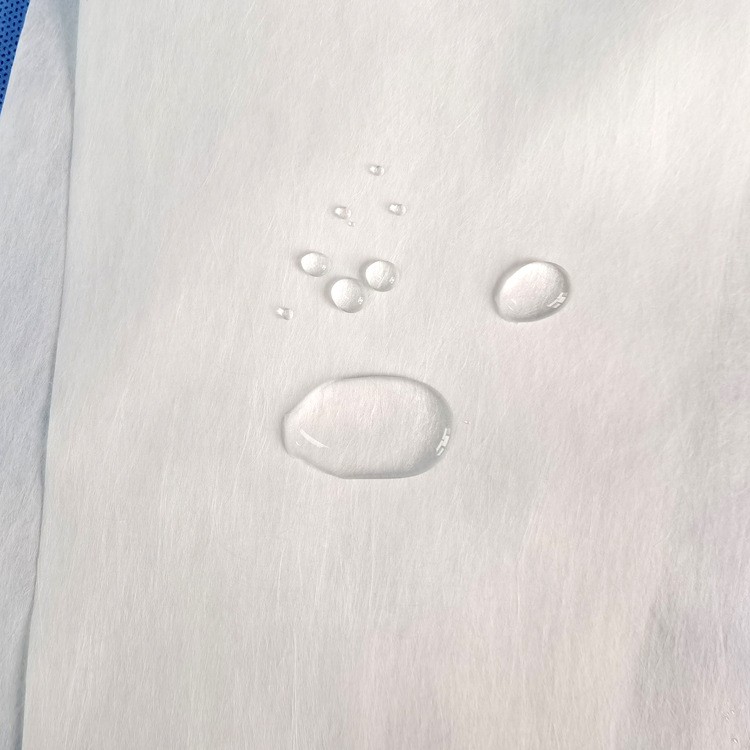

Meltblown non woven fabric has excellent filtration, insulation, oil absorption and heat insulation, and is widely used in the field of medical masks. Put forward suggestions for the future development of meltblown non woven industry, which can provide reference for its benign development.

Comment(0)

You can comment after

SIGN IN