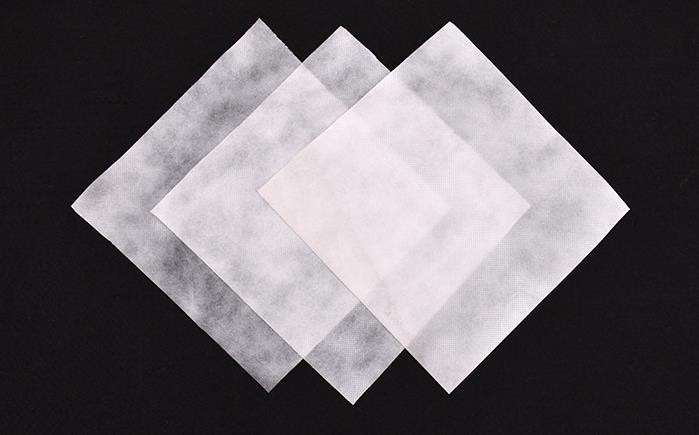

With the development and continuous improvement of nonwoven technology, the production process of medical non woven is relatively mature. Spunbonded method, melt blown method and SMS composite technology have become important processing technologies of medical non woven fabric products.

In China, spunbonded non woven products are still dominated by PP fibers, but skin core type, island type, orange petal type two-component fibers and multi-component fibers have attracted more and more attention. For example, the nonwovens made of pp/pe juxtaposed two-component fibers not only have a fluffy fabric structure, but also have better softness and hand feel than single component fibers or leather core fibers with the same component. It has great advantages in manufacturing surface materials of medical and health products. For spunbonded technology, wide slit negative pressure drafting system is the most widely used spunbonded drafting technology. 90% of polypropylene spunbonded systems in China adopt this process, which is also the first choice of spunbonded systems in SMS production line. The fiber produced by wide slit negative pressure drafting process is relatively thin, with good uniformity, good hand feeling, relatively small longitudinal and transverse strength, low energy consumption and low elongation at break. The product has been widely used in the field of medical and health care.

Melt blown method is very practical. Its products can be used in many fields. Among them, in the health and medical fields, it is used to make filter media, diapers, respiratory masks, etc. The main raw materials of melt blown production are PP, PE, polystyrene, PLA, etc.

Melt blown method is mainly used to prepare superfine fibers. The non woven produced has high porosity and small pore size. It is used as medical protective materials, and its barrier performance is better than spunbonded cloth and Spunlaced cloth. Because the fiber diameter is small, the fiber is randomly oriented, has a three-dimensional structure, and has high porosity, the melt blown material is also suitable for bone or knee cartilage scaffolds.

With the continuous development of composite technology, the combination of spunbonded and other nonwoven technologies is also common in the production of medical products, such as SMS composite technology, spunbonded and Spunlaced Composite Technology. In SMS production line, spunbonded system can be single component or two-component, while melt blown system is generally single component. In the production process of spunbonded system production line, there are SS and SSS models. SMS products that are relatively common in the market include SSMS, SMMs, ssmms, smmms, etc. With the combination and arrangement of spunbonded system and melt blown system, some production lines will reserve physical space for the installation of X system, and the production lines will be adjusted according to product requirements, such as smxs, ssmmxs and other production lines.

In recent years, spunbonded and spunlaced composite technology has attracted people's attention. It uses the physical action of high-speed water flow to reinforce the fiber mesh, and does not involve any chemical reagent in the reinforcement process. It is relatively safe and reliable, and realizes green and environmental protection production. The feel of spunlaced products is close to that of traditional textiles. Its material is soft, hygroscopic and high-strength, providing good application performance for medical non woven.

With the continuous development of non woven fabric production technology, non woven is more and more widely used in the medical and health industry, which has great development potential and expansion space.

Comment(0)

You can comment after

SIGN IN