Polylactic acid is a polyester polymer material, which can be completely biodegradable. Its application in melt spun new technology and Multi FormTM non woven can further expand its market. This paper briefly introduces the technology of Multi FormTM non woven fabric and the development and application of polylactic acid in this field.

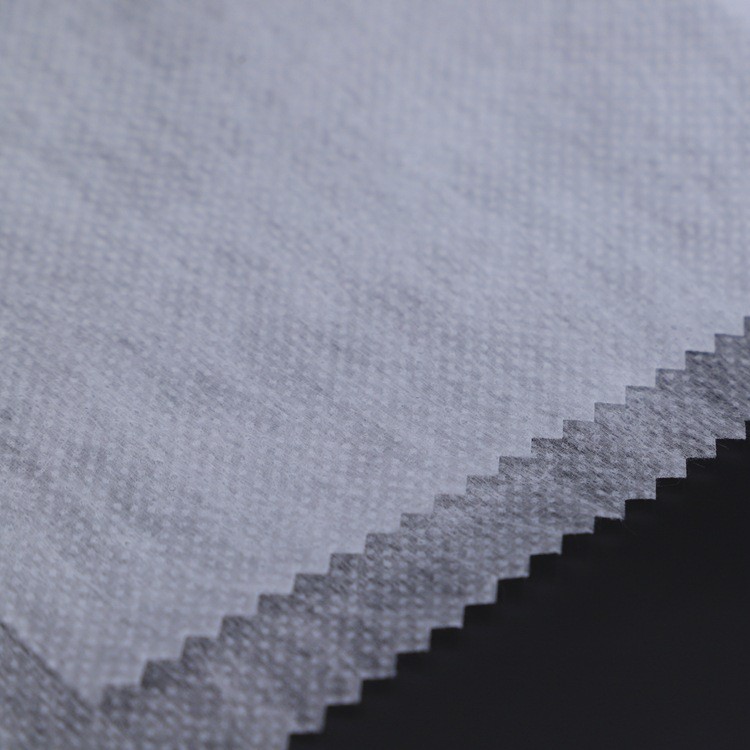

In 2015, the American extrusion group took the lead in launching a new type of Gena ™ The melt blown system is called Multi FormTM. Multi FormTM cloth is a kind of nonwoven material made of superfine fibers with a diameter of only 1/8 of man-made fibers, wood pulp fibers and other functional fibers produced by melt blown method through advanced dry process. Multi FormTM cloth is born out of the traditional melt blown cloth process, and the raw material is still pp. the product has the characteristics of melt blown cloth and Spunlaced cloth at the same time, but compared with spunlaced nonwoven process, it has the absolute advantages of short process and high output; Compared with traditional melt blown cloth, it has better fluffy degree, absorption, coverage, hand feel, etc. At present, with its unique excellent performance, Multi FormTM non woven has become a special raw material for baby wipes Huggies (curiosity) and Kleenex (Shujie) under Kimberly Clark group, a giant in the sanitary products industry.

Multi FormTM is still in its infancy in China. Equipment manufacturers and material manufacturers in the melt spun industry have been set up in research and development, and a small amount of Multi FormTM cloth made of pp+ carpenter fiber has been produced. Using polylactic acid instead of PP as the main material and adding wood pulp fiber can be used to develop new popular cleaning materials such as bio based nonwoven materials, non woven materials that can be dispersed, and water absorbent composite cores, which are mainly used in the following five fields:

(1) Wiping materials: such as baby wipes, makeup removal wipes, household wipes, industrial wipes, etc;

(2) Absorbent core and guide layer materials of disposable sanitary products: such as female sanitary napkins, baby diapers, adult incontinence products, floor mops, trauma care, breast-feeding pads, etc;

(3) Liquid absorption and diffusion materials: medical bandages, surgical curtains, hole towels, absorbent blankets, oil absorbing materials, etc;

(4) Sound insulation and heat insulation materials: such as automobile sound insulation cotton, clothing heat insulation materials, etc;

(5) Filter material: water filter, air filter material, etc.

With the continuous increase of national "plastic ban", "plastic limit" and other environmental protection policies, people's awareness of environmental protection and social responsibility continue to improve. At the same time, domestic melt spunnon woven is facing the problem of overcapacity. Melt spun enterprises have a strong demand for product differentiation strategy. The development and application of melt spunnon woven polylactic acid fabric is the general trend and has a promising future.

Comment(0)

You can comment after

SIGN IN