COVID-19 broke out globally in 2020, and the demand for masks and disposable medical supplies increased sharply. Masks and other medical supplies have made positive contributions to epidemic prevention, and have also brought great pressure to environmental protection. Developing environment-friendly polylactic acid spinning and melting non woven has become the focus of social attention. This paper briefly introduces the development status, existing problems and Countermeasures of polylactic acid spinning melt non woven fabric.

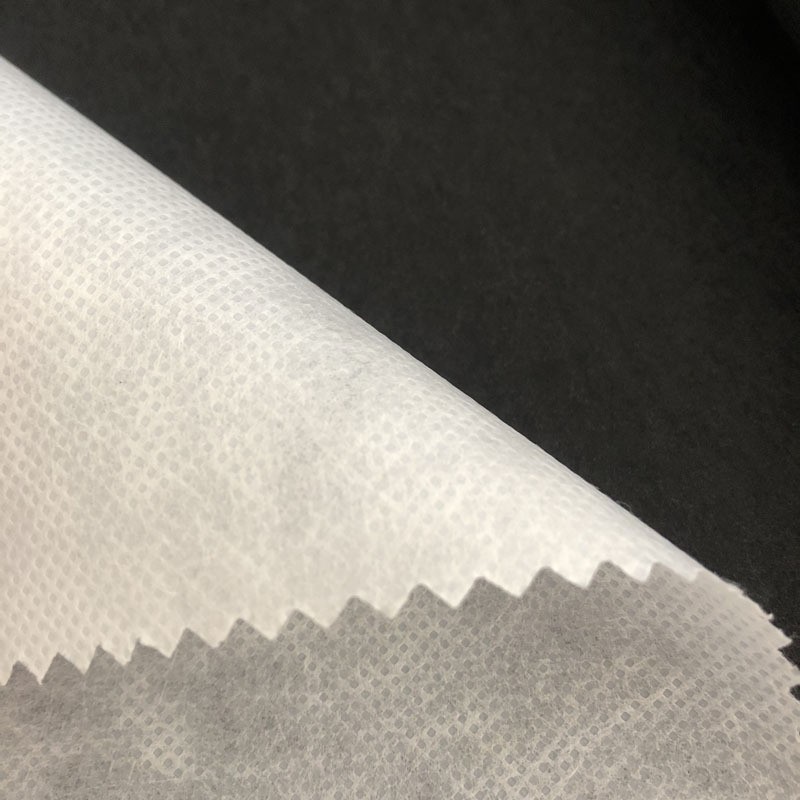

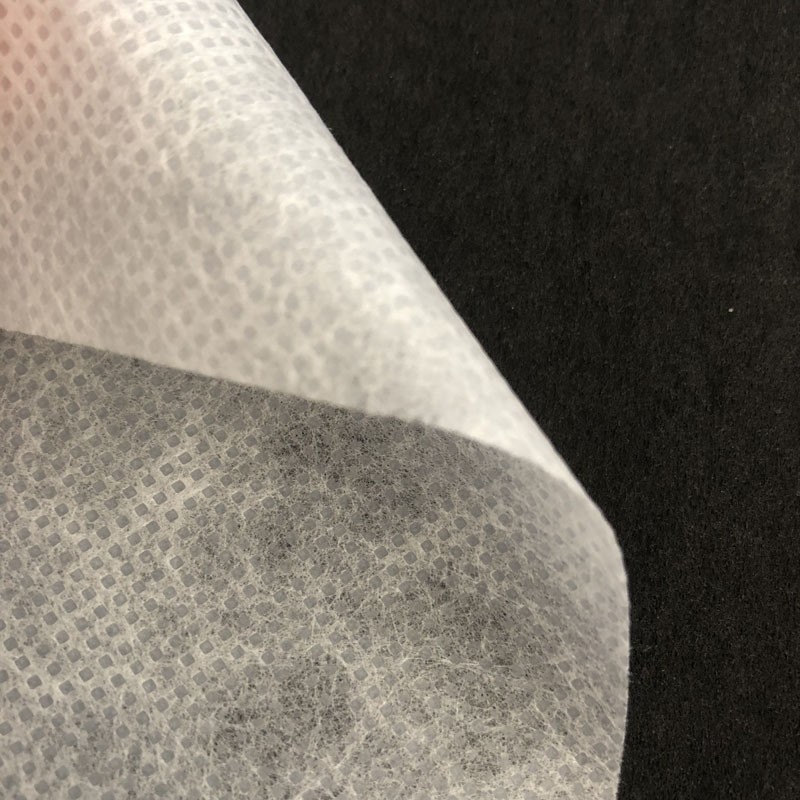

At present, there are more than 10 enterprises in China's textile melting industry that can mass produce polylactic acid spunbonded hot-rolled non woven. These enterprises usually use single die production, adjust some process parameters of the original PET spunbonded hot-rolled production line, and produce polylactic acid spunbonded cloth, with a minimum weight of 15 g / m2. The products are exported to Europe and other places for agricultural seedling cloth, etc; More products with high gram weight (80~110 grams / square meter) are produced and made into packaging products for export. Its application in domestic market is very few. Polylactic acid raw materials are mainly imported. With the gradual maturity of the technology of domestic polylactic acid raw material production enterprises, domestic materials began to be put into use.

Many years ago, in China, some universities and enterprises processed polylactic acid through research and development of melt blown non woven technology, but there was no mass production. The reason is the high cost of raw materials and limited market acceptance; In addition, using traditional PP melt blown cloth equipment to process polylactic acid, the production process is not mature enough. In particular, as a high-end filter material, polylactic acid melt blown cloth has a technical bottleneck in improving the filtration efficiency. Existing enterprises are exploring ways to improve filtration efficiency and reduce filtration resistance by modifying polylactic acid (maintaining degradability), adding electret masterbatch, and treating polylactic acid melt blown cloth with electret.

At present, the development and utilization of polylactic acid spinning melt non woven is still very few in China, mainly because: first, the price of raw material polylactic acid is too high, which is 3~4 times that of PP. as a disposable product, its cost is high and its market acceptance is low; Secondly, the single machine capacity of the spinning and melting production line is large, and the order volume of polylactic acid is small, which cannot meet the constant production, resulting in low production efficiency, large consumption of raw materials for production line replacement, and limited enterprise development enthusiasm. With the expansion of the production scale of domestic raw materials of polylactic acid, the improvement of process technology and the reduction of production costs, the price of raw materials will decline. Spinning and melting production enterprises should segment the market, and can target some high-end consumers who pay attention to green and healthy products, such as mother and baby products; At the same time, we should cooperate with the guidance and support of policies to form a consensus of the whole society and make environmental protection a necessity.

At present, most disposable medical and health products in China are PP and pet spun non woven. These non degradable products cause a great burden on the environment after being discarded. But at the same time, it also provides a broad development space and promising prospect for the development and application of polylactic acid melt spun non woven fabric in line with the trend of the times.

Comment(0)

You can comment after

SIGN IN