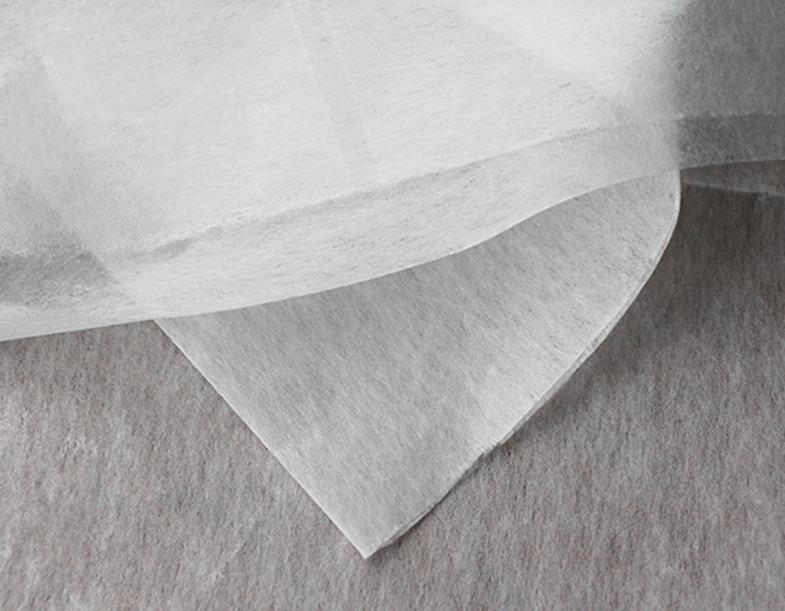

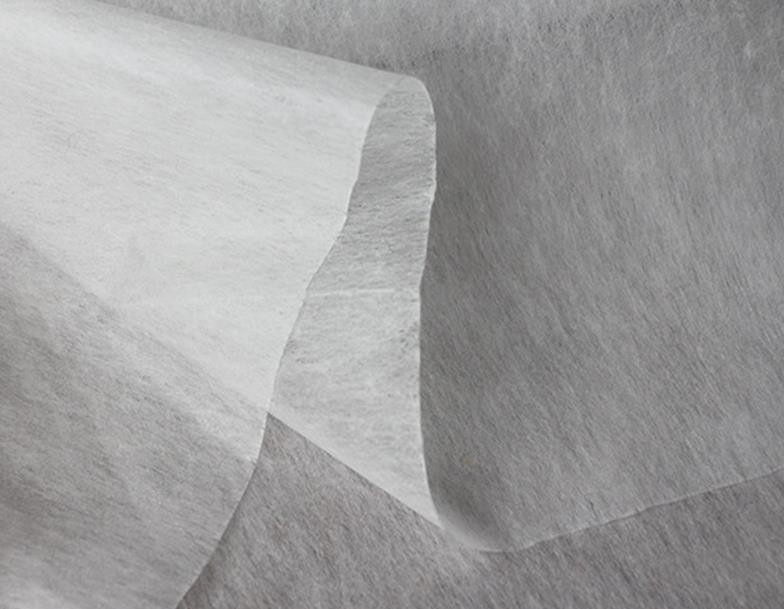

Factors such as metering pump speed, hot rolling temperature and spinning temperature will affect its physical properties in the process of preparing biodegradable polypropylene composite spunbond non woven fabric. In this paper, the thermal properties of fibers before and after high-speed flow field draft were analyzed, and the properties of biodegradable polypropylene composite spunbond non woven were analyzed.

By setting different metering pump speeds, the fiber properties of the prepared composite fibers and the performance indicators of the composite spunbonded fabric are analyzed, so that the best metering pump speed can be obtained by integrating the fiber properties of the composite spunbonded fabric and the properties of the non-woven fabric.

Taking the prepared biodegradable polypropylene composite spunbond non woven fabric as an example, the analysis results are as follows: the properties such as fiber diameter, linear density and breaking strength increase with the increase of metering pump speed, and the thickness, tensile strength and weight of the prepared composite spunbonded fabric also increase with the increase of metering pump speed. Therefore, the speed of metering pump has a positive correlation with the properties of biodegradable polypropylene composite fiber and spunbonded fabric. In order to obtain the good performance of biodegradable polypropylene composite spunbonded fabric, the speed of metering pump can be increased under appropriate conditions to prepare composite spunbonded fabric with good performance.

By fixing other preparation process parameters and setting different hot rolling temperature of the rolling mill, the influence of hot rolling temperature on the properties of the prepared composite fiber was studied and analyzed. It is found that when the hot rolling reinforcement temperature of the rolling mill is too low, the hot-rolled fiber cannot be fully melted, resulting in unclear lines and poor hand feel.

Taking the biodegradable polypropylene composite spunbond non woven fabric prepared as an example, when the hot rolling reinforcement temperature reaches 70 ℃, the grain of the composite fiber is clear and slightly adhered to the roll. Therefore, 70 ℃ reaches the upper limit of the reinforcement temperature. By setting the hot rolling temperature of the rolling mill to 40, 50, 60, 70 ℃ respectively to analyze its performance indicators, the results are as follows: with the increase of the hot rolling reinforcement temperature of the rolling mill, the thickness of the composite spunbonded fabric decreases, the tensile strength increases, tends to be stable, and the gram weight first increases and then decreases. Through comprehensive analysis of various performance indexes, it can be concluded that when the hot rolling temperature of the mill is 60 ℃, the tensile strength of the prepared composite spunbonded fabric reaches the maximum.

Fix other preparation process parameters, set different spinning temperatures for experiments, and analyze the influence of spinning temperature on the properties of the prepared composite fiber and biodegradable polypropylene composite spunbonded fabric.

Taking the biodegradable polypropylene composite spunbond non woven fabric as an example, when the rotating speed of the fixed metering pump is 25r/min and the hot rolling temperature is 60 ℃, the experimental results are as follows: when the spinning temperature reaches 170 ℃, the properties of the prepared composite fiber and composite spunbonded fabric reach the best.

By studying and analyzing the properties of the biodegradable polypropylene composite spunbond non woven fabric, the best process parameters affecting its properties such as metering pump speed, hot rolling temperature and spinning temperature are obtained, so as to realize the effective preparation of biodegradable polypropylene composite spunbond non woven.

Comment(0)

You can comment after

SIGN IN