Affected by the COVID-19, non medical protective mask, as one of the important protective articles, has quickly become a popular product. However, with the increase of the output of non medical mask, the quality and safety problems of various products have also appeared.

According to the national supervision and random inspection in 2020, 1670 batches of non medical protective masks were randomly inspected in 2020, and 565 batches were unqualified, with an overall unqualified rate of 33.8%. Among them, filtration efficiency and protective effect are the biggest reasons for unqualified, accounting for 27% of the total number of unqualified batches 9% and 23%. At the same time, 73.7% of the reasons for recalling this kind of mask in 2020 are the unqualified protective effect, followed by 22.2% of the unqualified filtration efficiency.

According to the above product quality and safety supervision data, the non medical protective mask mainly has the following quality problems.

First, the logo is not standardized. Some enterprises did not indicate the actual value on the package, nor did they clearly state the purpose of the product. Under the existing signs, it is difficult for consumers to know the protection level of child protective masks and daily protective masks. At the same time, most non medical protective mask products do not indicate the filtration efficiency of particulate matter, but only the bacterial filtration rate ≥ 95%, which has the risk of misleading consumers.

Second, the filtration efficiency is unqualified. Filtration efficiency refers to the percentage of target impurities filtered by the mask under the specified detection conditions. It is also divided into particulate matter and bacterial filtration efficiency. It is used to measure the filtering effect of the mask on submicron particles and the ability of the mask to filter out bacteria when attacked by aerosols containing bacteria. If the filtration efficiency is not qualified, it will lead to the phenomenon of "wearing without prevention", increasing the risk of disease of the wearer.

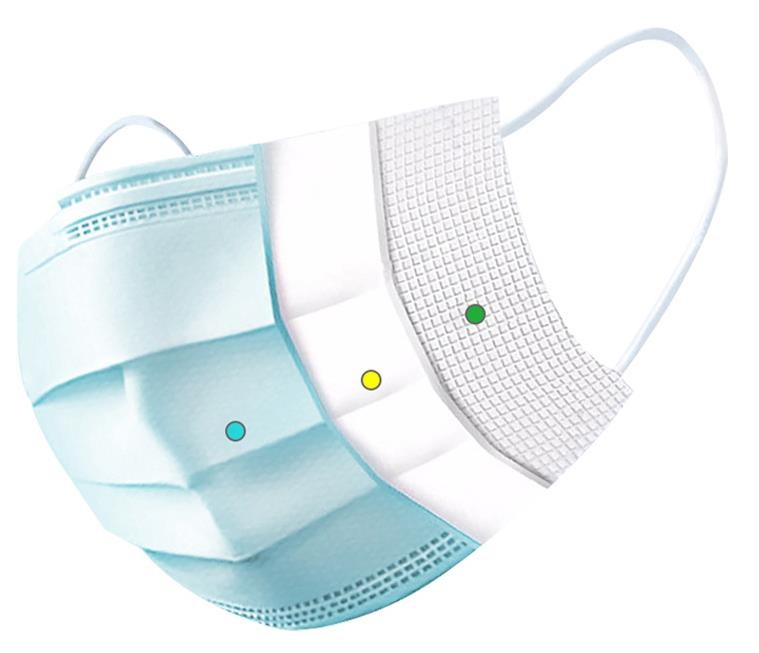

Third, the protective effect is not up to standard. Protective effect refers to the ability of the mask to prevent environmental particles from entering the mask on the standard head mold, which is one of the important indicators to measure the performance of the mask. The protective effect is closely related to the filtering performance and facial fit of the material.

Fourth, respiratory resistance is unqualified. Respiratory resistance refers to the resistance of the filter layer to the flow of filtered gas in the process of respiratory filtration, which is divided into pressure difference, ventilation resistance, expiratory resistance and inspiratory resistance. When wearing a mask, it is necessary to completely cover the mouth and nose. If the respiratory resistance of the mask is too large, it will affect the normal breathing of the human body, resulting in delayed oxygen inhalation and hypoxia.

Fifth, the breaking strength of the joint between the mask belt and the mask body is unqualified. The mask strap is a rope strap that secures the mask to the head. The breaking strength includes the connection strength between the mask belt and the mask belt and the mask body, which reflects the physical structure of the mask. If this indicator is not qualified, consumers will not be able to wear masks normally, or there is a risk of face exposure when wearing masks.

Sixth, the pH value is unqualified. The pH value reflects the pH value of the product (the normal range is 4~8.5). When the pH value of the mask exceeds the normal value, it will destroy the weak acidic substances on the skin (the surface of healthy skin is weak acidic). Wearing it for a long time will stimulate human skin, cause skin allergy and other adverse reactions, and endanger the health of consumers.

At present, non medical protective mask has become one of people's daily necessities. Understanding the current situation and problems of non medical mask product quality at this stage is conducive to promoting the benign development of the industry.

Comment(0)

You can comment after

SIGN IN