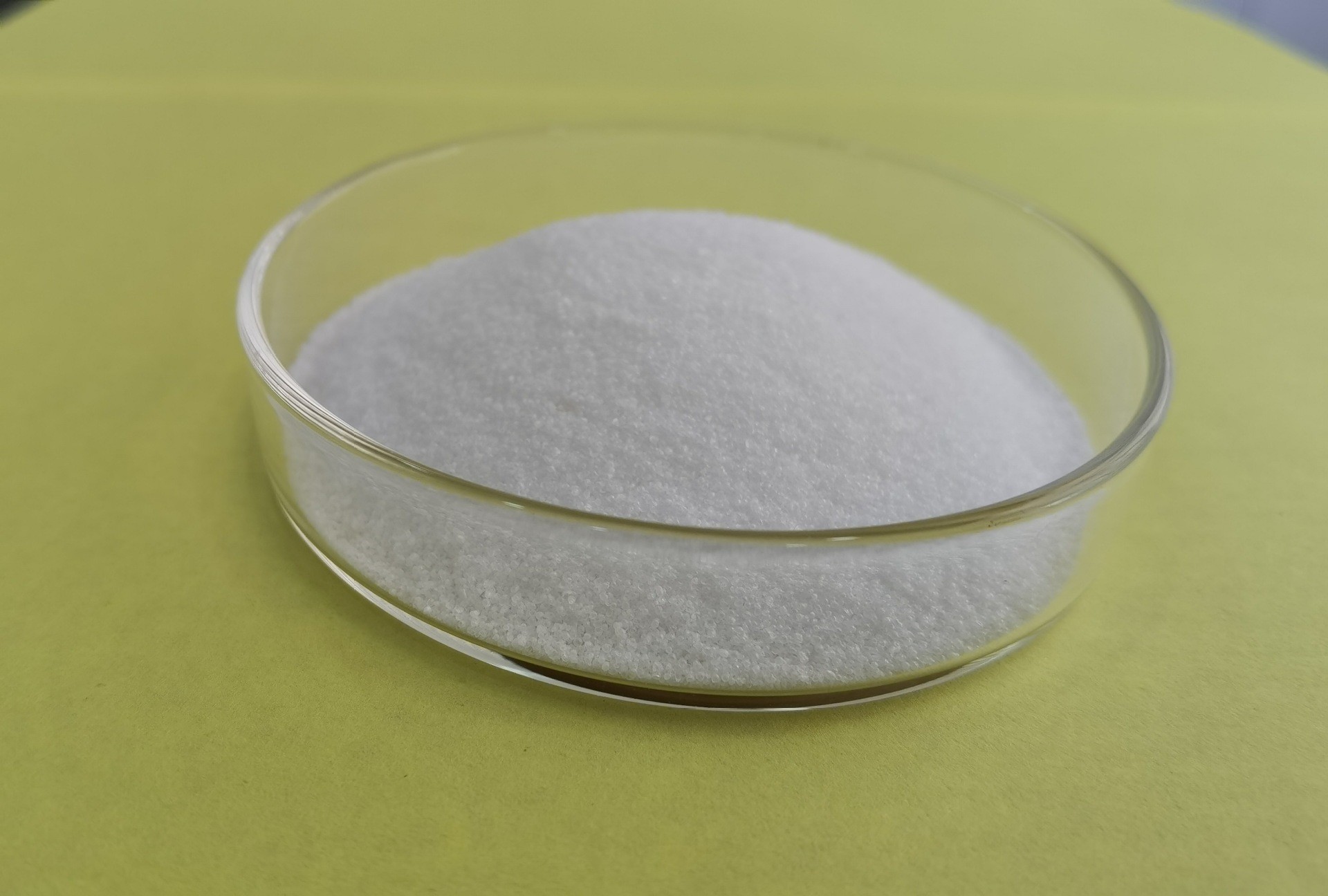

Since the 1980s, super absorbent polymer has been widely studied as a special and advanced material. Because of its excellent water absorption performance, it has been well used in many fields. This paper analyzes the process conditions of SAP powder.

A large number of research data show that 2m3 reactor is the best choice for super absorbent polymer during neutralization reaction. If the reactor selected in the production process has no refrigeration function, it can be cooled by cooling circulating water. If this type of reactor is selected, it is better to choose the specification between 0.6~0.83m3, which is conducive to the implementation of cooling measures. If the volume of the reactor selected in the production process is too large, the reaction time should be controlled at about 30min while cooling down.

Before the polymerization of super absorbent polymer, workers need to use activated carbon to remove the polymerization inhibitor. In this process, oxygen is usually treated with nitrogen. In the production process, if the initiator uses the oxidation-reduction composite system, the activity of the material will be greatly reduced, resulting in relatively low requirements for external temperature. The chromaticity of the product produced by this process is also poor, but the purity of the finished product is relatively high.

In the granulation process of super absorbent polymer, large granulator is mainly used for granulation. During this period, lubrication should be done well, so surfactant solution is required. It should be noted that appropriate active agent varieties should be used in the production process, and the dose of the whole process should be strictly controlled.

The water absorption of super absorbent polymer produced by the above process will reach about 500~700 times. If higher water absorption is required, subsequent treatment is required. At present, the commonly used method is to change the dosage of crosslinking agent without changing other production processes and production processes. By adjusting the amount of crosslinking agent, the performance of the material can be greatly improved.

After decades of research and exploration, the research on the properties and applications of super absorbent polymer materials is approaching maturity, and the industrial production scale has exceeded one million tons. Understanding the process conditions of SAP powder material will help people better understand this material.

Comment(0)

You can comment after

SIGN IN