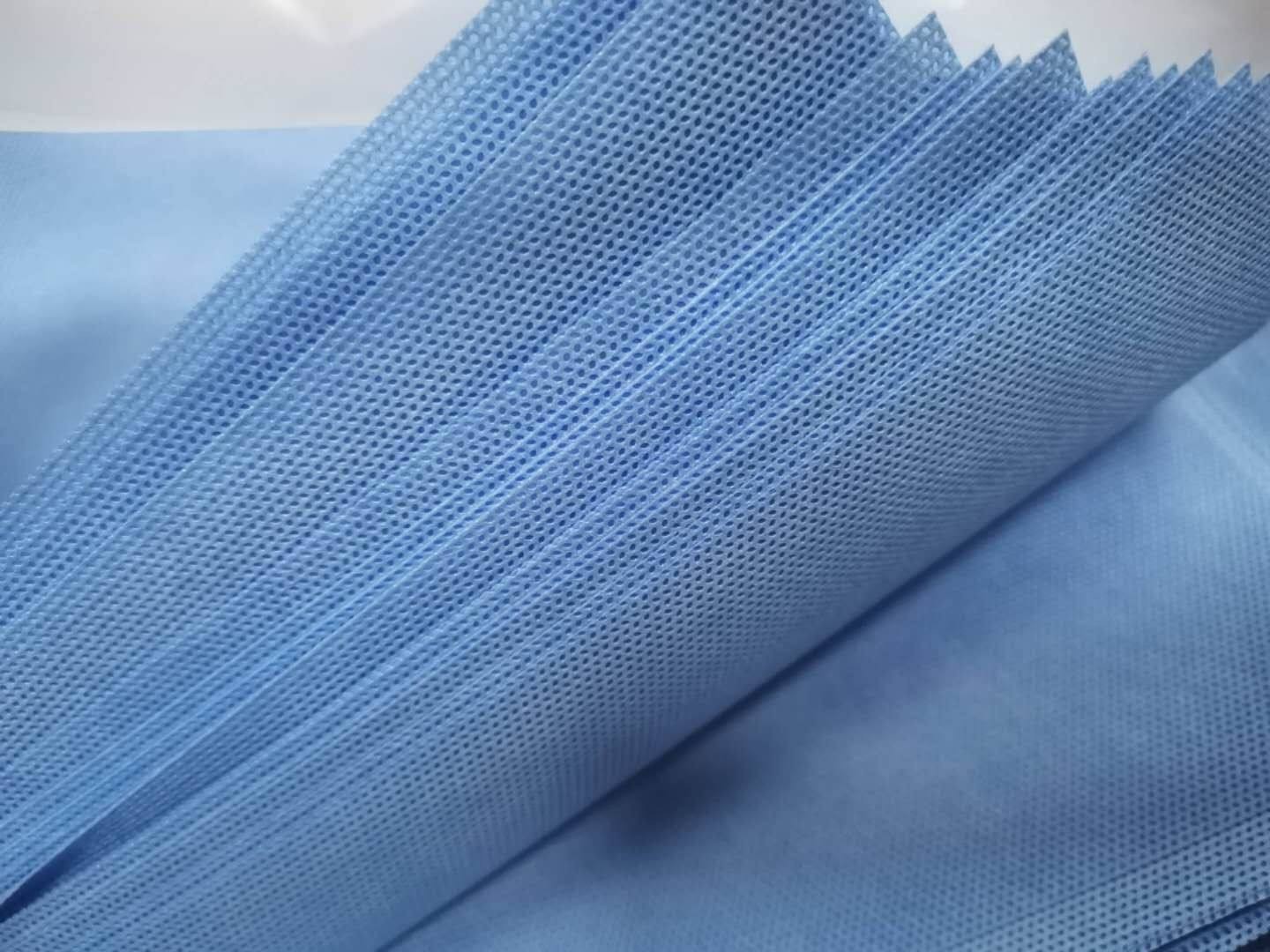

Medical non woven refers to the consumable auxiliary supplies used by medical institutions in medical, prevention, health care and other related activities, which mainly play the role of isolation and protection, promoting wound healing, bandaging and fixation. This paper briefly expounds the performance requirements and advantages of medical non woven fabric.

The performance requirements of medical non woven mainly include barrier, comfort, mechanical properties, antistatic properties, etc.

When human body is exposed to dangerous environment, barrier is a necessary performance of protective materials. It can protect medical staff from bacteria. The main requirements are to prevent the penetration of water, blood, alcohol and other liquids, isolate bacteria, prevent microorganisms from invading the human body, and reduce the probability of secondary infection or even cross infection.

Comfort means that the material should make patients or medical personnel feel comfortable during use. This comfort can be expressed by the thickness, permeability and moisture permeability, drapability and skin affinity of the material, among which permeability and moisture permeability are the most important.

Mechanical property refers to that in the process of clinical application, medical personnel should ensure that the material has a certain strength of resistance to fracture, bursting and tearing, so as to avoid the material breaking due to insufficient strength, being punctured by sharp objects, and the material itself or the place where it is connected.

Antistatic refers to preventing or reducing the electrostatic effect between protective clothing and human body and medical devices.

(1) The processing process is short and the cost is low. It is suitable for manufacturing disposable products, which can prevent cross infection between patients and medical staff, and reduce the treatment cost after recycling;

(2) High porosity, good ventilation and moisture permeability, good comfort, which can improve the comfort of medical staff and patients;

(3) Adhesive is hardly used in the processing process, and there are few impurities, which can effectively reduce the risk of infection of patients;

(4) The material has smooth surface, less hairiness and stable quality, which can effectively prevent the problem of floc falling, and the affected part of the patient is not easy to adhere, which can further reduce the risk of infection and alleviate the pain of the patient;

(5) The production cost is low and the product price is low. Compared with other weaving methods, non woven has more diversified processing methods. For example, its excellent filtration characteristics lie in its unique three-dimensional structure, which can improve the diffusion efficiency through the mesh pores, so as to improve the filtration efficiency and enhance the isolation and protection of the material against bacteria and viruses.

From SARS in 2003 to the global outbreak of avian influenza, swine flu and Ebola virus, people's awareness of self-protection and health has been continuously enhanced, and the demand for medical non woven is also growing rapidly. Understanding the performance requirements and advantages of medical non woven fabric will help people better understand this material.

Comment(0)

You can comment after

SIGN IN