Polyolefin breathable film is a kind of polyolefin filled with calcium carbonate, silicon dioxide, clay and titanium dioxide as inorganic fillers, which is made into a film by calendering, casting or blow molding, and then forms a breathable film sheet by unidirectional or biaxial stretching. It is widely used in baby diapers, women's sanitary napkins, protective clothing, building waterproof materials and other products. This research started late in China. This paper mainly studies the relationship between the molding process and the performance of polyolefin breathable film.

When the tensile ratio is 2.0, the longitudinal elongation tends to increase with the increase of tensile temperature, while when the tensile temperature is high, the increase of transverse elongation slows down and remains at a certain level. When the tensile strength reaches 85 ℃, the maximum value appears.

With the increase of tensile temperature, the permeability decreases gradually. To sum up, when the tensile temperature is close to the softening point, the comprehensive performance of breathable film is better, the film appearance is better, the stripes basically disappear, and the hand feel is softer.

The elongation of breathable film decreases with the increase of tensile ratio, which decreases significantly in the longitudinal direction and slowly in the transverse direction. In a certain range of tensile ratio, the longitudinal tensile strength is basically not affected by the tensile ratio, while the transverse strength decreases significantly with the increase of the tensile ratio.

The water vapor transmission increases gradually with the increase of tensile ratio, because the larger the tensile ratio is, the larger the micropore of the film is, and the higher the porosity is.

Under the same process, the tensile strength of breathable film is less affected by film thickness, but the elongation increases with the increase of film thickness; At the same tensile ratio, the porosity has little relationship with thickness, and the permeability decreases with the increase of thickness.

The influence of draw ratio and film thickness on the properties of breathable film prepared by blowing process is basically the same as that of tape casting process. Under the same blowing ratio and drawing ratio, the greater the thickness of the film, the better the tensile properties of the film, but the lower the transmittance of water vapor; Under the same blowing ratio and film thickness, the larger the stretching ratio is, the better the permeability is, and the worse the stretching performance is; Under the same stretching ratio and film thickness, with the increase of the blowing ratio, the permeability of the film increases slightly, and the stretching property decreases slightly.

Comparing the two film making processes, it can be found that under the same draw ratio and film thickness, the permeability of the film is slightly higher than that of the tape casting process, and the difference between the longitudinal and transverse tensile properties of the film is less than that of the tape casting process.

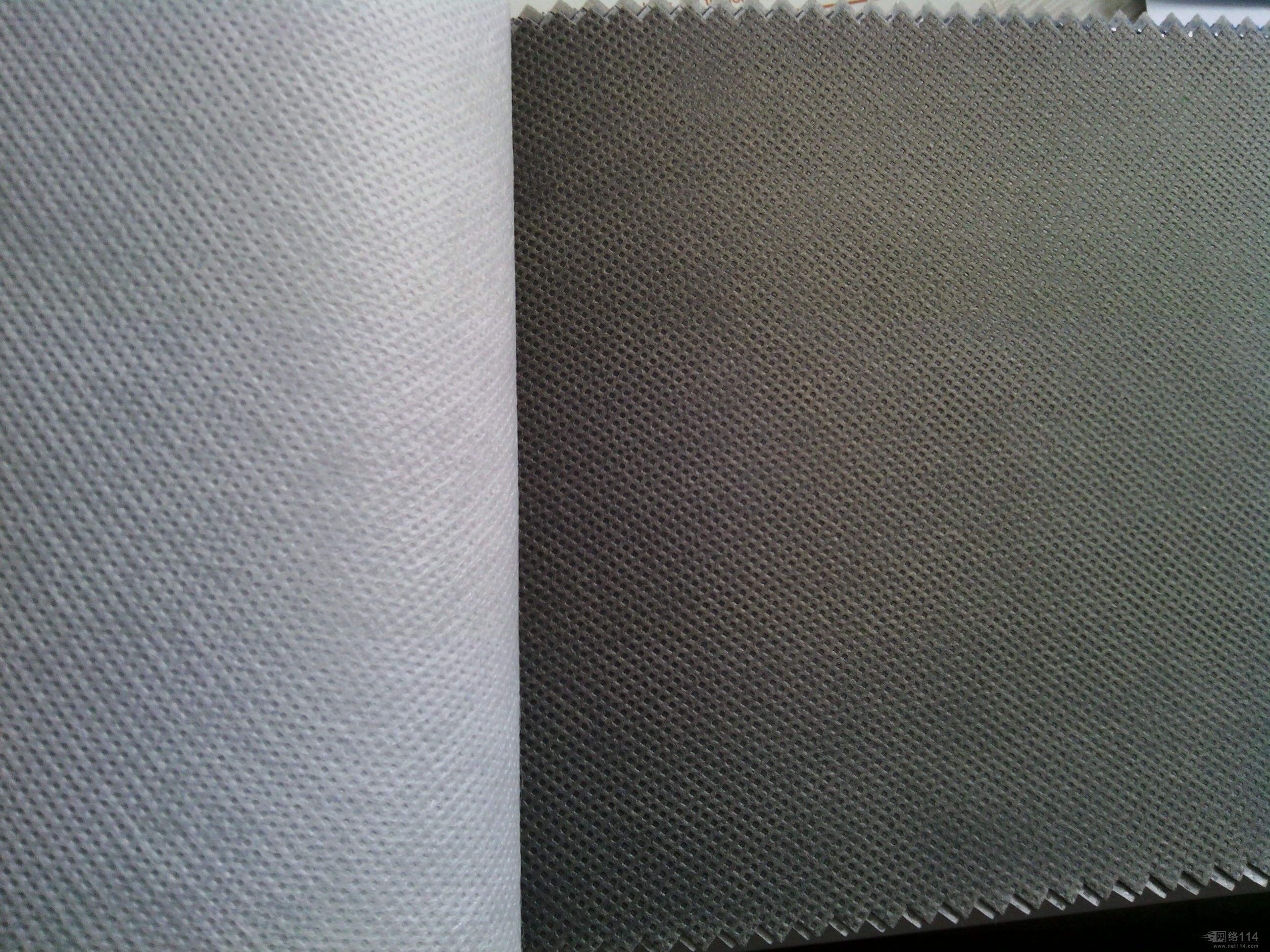

From the SEM of the breathable film surface, it can be seen from the photos that the pore sizes formed in the film are different with different draw ratios. The larger the draw ratio and the larger the pore diameter, the better the permeability.

From the SEM of its cross section, it can be inferred from the photos that the gas molecules actually pass through a sinuous channel, from one side of the film to the other side of the film. Therefore, when the film thickness increases, although the porosity is basically the same, the permeability decreases because the channel path through which the gas passes becomes longer.

Molding process is the main factor affecting the performance of specific polyolefin breathable film special materials:

(1) When the tensile temperature is 85 ℃, the breathable film sheet has good appearance and comprehensive properties; With the increase of tensile ratio, the pore diameter increases, the permeability increases, and the tensile property becomes worse; The permeability decreases with the increase of thickness.

(2) The influence of drawing temperature, drawing ratio and film thickness on film properties has little to do with film manufacturing process. However, due to the existence of horizontal expansion and stretching in the film blowing process, the permeability and the longitudinal and transverse difference of stretching are somewhat different from the casting process.

Comment(0)

You can comment after

SIGN IN