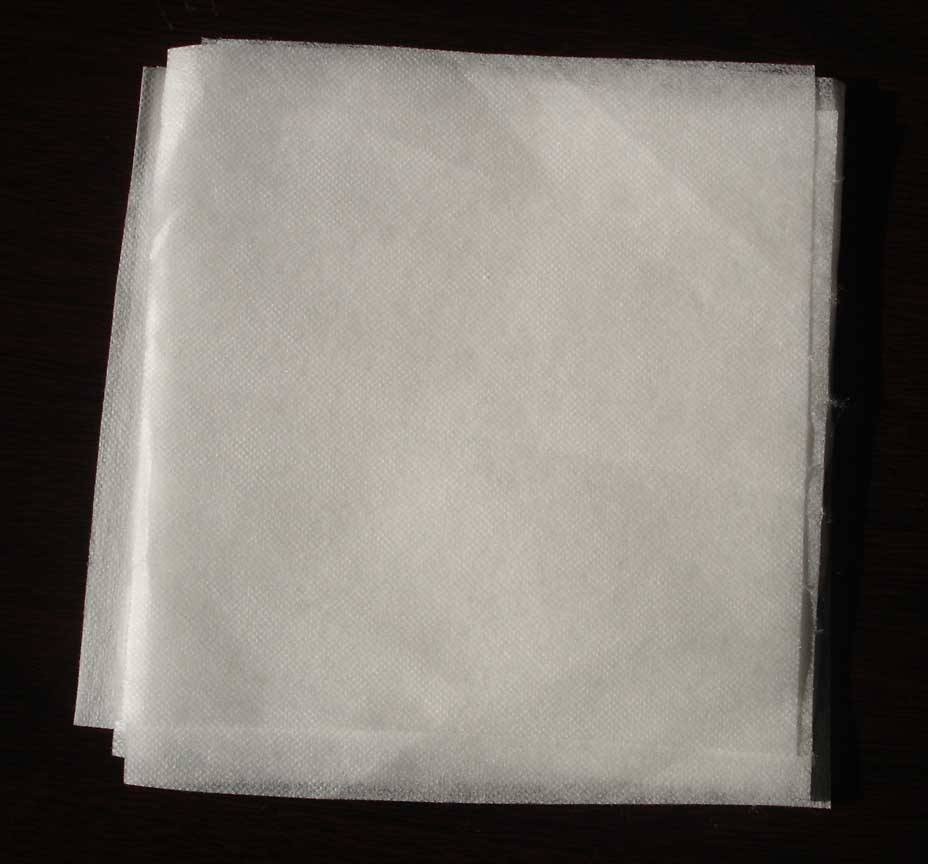

According to the national unified classification standard, household paper is divided into 24 kinds, and tissue lining paper belongs to a special kind of household paper. At present, it is mainly used in sanitary napkins, diapers, composite cores, etc., and plays an irreplaceable role in the field of disposable sanitary products. This paper mainly expounds the technological scheme of tissue paper.

For the size ratio of tissue lining paper, by analyzing the physical properties of base paper produced with different proportions of softwood pulp and hardwood pulp, according to the characteristics of paper machine and the control of production conditions, the ratio of softwood pulp and hardwood pulp is finally determined to be 7:3.

As for the pulping process of tissue lining paper, generally speaking, the evenness and tensile strength of base paper are related to the pulping quality. In order to obtain good evenness, reduce the cutting effect of fiber and improve the tensile strength of base paper, three double disc mills should be selected for series grinding during pulping. The refining process is as follows: the refining concentration is 4.0%~4.5%, the beating degree is 35~37 °Sr, and the wet weight of fiber is 5.5 ~ 7.0g.

In the production process, the quantity must be strictly controlled. The quantitative size is closely related to the stability of on-line concentration, sizing pressure, flow and the opening size of weir plate. The main factors affecting the dry and wet tensile strength of base paper are the beating degree of pulp, the ratio of softwood pulp to hardwood pulp, and the amount of wet strength agent. Therefore, the premise of ensuring the dry and wet tensile strength of base paper is to formulate an appropriate beating degree, control the quantity in the production process, control the proportion of coniferous pulp and hardwood pulp, and the dosage of wet strength agent. The quantitative size of the base paper also affects the air permeability. At the same time, the selection of forming mesh is also closely related to air permeability. In the actual production process, the dust degree is the focus of tissue lining paper control. The control of dust level is closely related to the cleanliness in the production process, including the washing cycle, the selection of recycled waste paper, the rational use of fungicides, and the regular washing of rotten pulp in the production process. If there are mistakes in these aspects, dust will appear.

With the rapid development of the household paper industry in China, the relevant technology and research and development have been paid more and more attention by all parties in the paper industry. As a household paper that wraps the absorbent core of sanitary products such as sanitary napkins and diapers, tissue lining paper is an indispensable part of the production of sanitary products. Understanding the technological scheme of tissue paper is conducive to its further development.

Comment(0)

You can comment after

SIGN IN