With the development and progress of society, people's health awareness is gradually enhanced, and sanitary products are developing rapidly. Breathable film is becoming more and more popular in the sanitary products market. This paper briefly introduces printed film in roll and how to test its permeability and safety.

Polyolefin microporous breathable film is made by filling polyolefin substrate with inorganic filler through extrusion and stretching (MDO) film-forming process.

Polyolefin microporous breathable film used in sanitary products industry is made of polyethylene substrate and calcium carbonate. Calcium carbonate with particle size of 1.5 ~ 8 µ m shall be used, and its content shall not exceed 55% by mass.

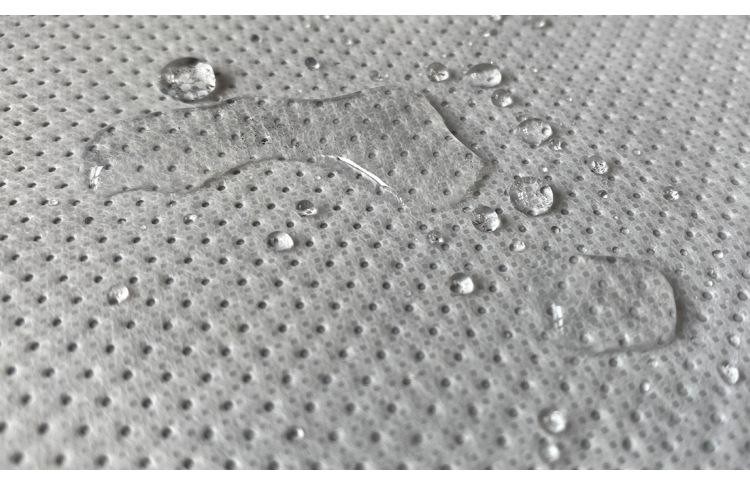

This kind of membrane has moisture permeable effect, and the key lies in its special surface and interlayer structure. It has a unique microporous structure. Each square centimeter of film has thousands of air permeable pores. These high-density special structure micropores distributed on the film can not only prevent liquid leakage, but also make water vapor molecules pass smoothly, so they have air permeability and impermeability.

(1) Air permeability test

Generally speaking, there are two testing methods for air permeability, namely, weight gain method and weight loss method.

The weight increase method is to add a certain amount of anhydrous calcium chloride into the container, seal it with the membrane to be tested, place it for a certain time under certain conditions, and then measure the mass of anhydrous calcium chloride in the container. Weight loss method is to add a certain amount of distilled water into the container, seal it with the membrane to be tested, and place it for a certain time under certain conditions to measure the quality of distilled water in the container.

The final test results are converted into the water quality of breathable film per unit area for 24 hours to express the permeability of the film.

(2) Security test

For the safety (anti leakage) of the membrane, the fabric hydrostatic pressure tester is often used in the industry to measure the hydrostatic pressure resistance of the membrane to indicate its leakage. However, it has been proved that a single hydrostatic pressure resistance index can not fully represent the impermeability of the membrane. Moreover, the one-sided pursuit of hydrostatic pressure resistance will increase the risk of leakage and cause consumer complaints.

To this end, we have introduced a new evaluation index "permeability". There are two test methods for this index: one is to use filter paper as the carrier, add test solution, cover a layer of membrane to be tested, put a layer of toilet paper on it, press weights, and measure how much test solution the top toilet paper can absorb; The other is to use absorbent (sanitary napkin) as the carrier, add artificial blood, put the membrane to be tested under it, put a layer of filter paper under the membrane, and press a weight on the top to measure the amount of artificial blood absorbed by the filter paper. Experiments show that the permeability measured by these two methods can better achieve the safety of breathable film.

As one of the raw materials of sanitary products, with the development of society, breathable film is more and more widely used in the field of sanitary products. Understanding the testing methods of its permeability mechanism, permeability and safety will help people better use printed film in roll.

Comment(0)

You can comment after

SIGN IN