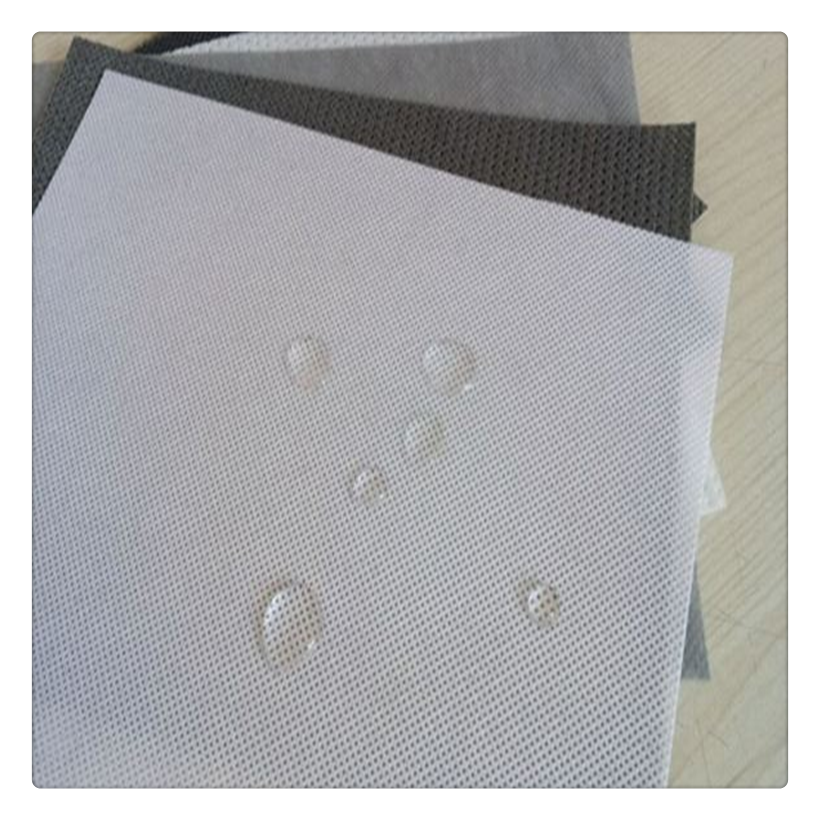

The full name of breathable PE film is "waterproof and breathable microporous membrane". It is a new type of breathable and impermeable polymer material, and its main component is polyethylene. Its skin friendly, high tensile strength and good moisture permeability are widely used in the field of sanitary products. Today, let's take a brief look at PE backsheet film.

Film forming principle of breathable film: PE+caco3 (master batch) - film forming - Stretching - breathable film

Breathable PE film is made by blending LDPE/LLDPE in polyethylene resin carrier, adding about 50% special calcium carbonate, extruding the film, and then directionally stretching a certain ratio. Because polyethylene resin is a kind of thermoplastic material, it can stretch and crystallize under certain conditions. During the stretching process, the interface between the polymer and the calcium carbonate particles peels off, and the interconnected sinuous pores or channels are formed around the calcium carbonate particles. It is these pores and channels that endow the film with air permeability (humidity) function, thus communicating the environment on both sides of the film.

(1) The inherent characteristics of the breathable membrane are the basis for the ultimate air permeability effect, but the structural design of personal hygiene products is the key.

(2) As a waterproof material, the safety of breathable PE film is the premise. Only on the premise of ensuring safety, can we talk about air permeability.

(3) It is necessary to use breathable membrane for sanitary products with "wide relatively wide", "thin thin, close fitting", "bag relatively closed" structure and long-term use (such as diapers, pads, etc.).

(4) Compared with ordinary PE embossing film, breathable film has its inherent shortcomings, so the product design should be good at avoiding shortcomings and giving full play to its strengths. For example, the transverse strength (CD) of the breathable film is low, the color is monotonous, and the thermal stability is poor.

(5) The final ventilation effect is proportional to the actual ventilation area of the membrane. When designing products, we should cherish and protect the effective air permeability area.

(6) The design of the final product shall consider the convection of the small environment.

(7) There is a time lag in the performance of breathable products on users.

Breathable PE film is used in diapers, sanitary napkins, medical mattresses, etc. there has always been a stable demand in Europe and the United States. However, the domestic sanitary material market is bound to mature with the demand for functionality and comfort, and the demand space for PE backsheet film will be larger and larger.

Comment(0)

You can comment after

SIGN IN