According to the different film making processes, the manufacture of microporous breathable membrane can be divided into film blowing method and casting method; According to different drawing processes, it can be divided into unidirectional drawing method, biaxial drawing method and local drawing method. Compared with PE casting embossing film, the manufacturing of breathable PE film has higher technical requirements. In the production process of PE backsheet film, the following aspects should be paid attention to.

(1) Resin selection

Rigid breathable film - high density polyethylene; Flexible breathable film - low density polyethylene; High tensile breathable film - high strength polyethylene; Printing (color registration, positioning and cutting) - high strength polyethylene

(2) Selection of calcium carbonate

Surface treatment of calcium carbonate: fluidity, extrusion stability, die mouth coking, pinhole, film mechanical properties, etc

Selection of calcium carbonate particle size: tensile property, moisture permeability, uniformity and processability

The choice of raw materials directly affects the machinability (such as coking time, extrusion stability, manufacturability of thin film material, pinhole defects, etc.) and physical properties (such as air permeability, water pressure resistance, thermal stability and mechanical properties, etc.) of breathable PE film. The choice of raw materials should first consider suitable for the physical requirements of customers on the film and the matching of processing equipment.

The main reason for holes and t-film coking in breathable PE film is the high raw material humidity, which will seriously affect the production efficiency and product quality of breathable film. Therefore, the production of breathable membrane requires strict humidity control requirements not only for raw material dehumidification (<250PPM), raw material transportation and flash recovery systems.

Stretching can enlarge the deviation of extrusion thickness, so the control of extrusion thickness is the premise to ensure the thickness uniformity of the final breathable PE film.

There are two necessary conditions for manufacturing breathable PE film, one is calcium carbonate, and the other is stretching. Therefore, stretching is very important in the manufacturing process of breathable membrane. Drawing temperature, drawing ratio, drawing rate and drawing gap are the four elements of drawing process. Its overall balance has a great influence on the permeability, mechanical properties, consistency and appearance of the breathable membrane.

The recovery and relaxation of rigid polymer segments after stretching by heat treatment is a necessary means to improve the stability of breathable PE film in the subsequent process and use process.

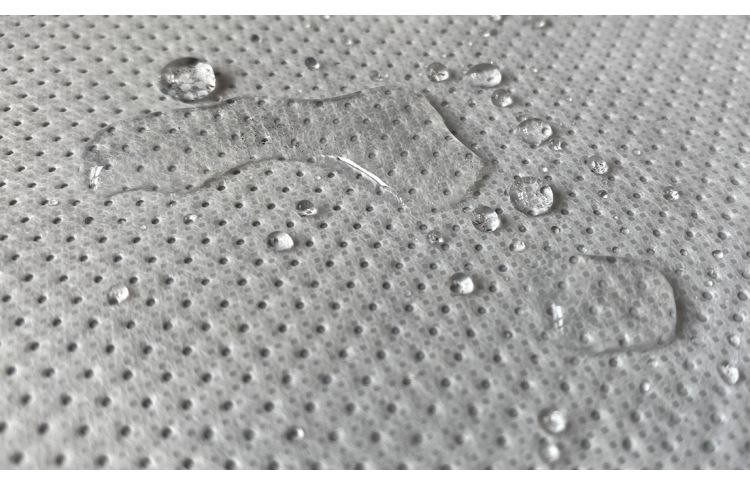

Breathable PE film is a functional material that is environment-friendly, breathable (steam) and water-proof (liquid, bacteria and dust). It is made by adding inert filler into PE carrier, film making and stretching. At present, it is widely used in personal health care products. Understanding the production technical principles of PE backsheet film can help people better understand this functional material.

Comment(0)

You can comment after

SIGN IN