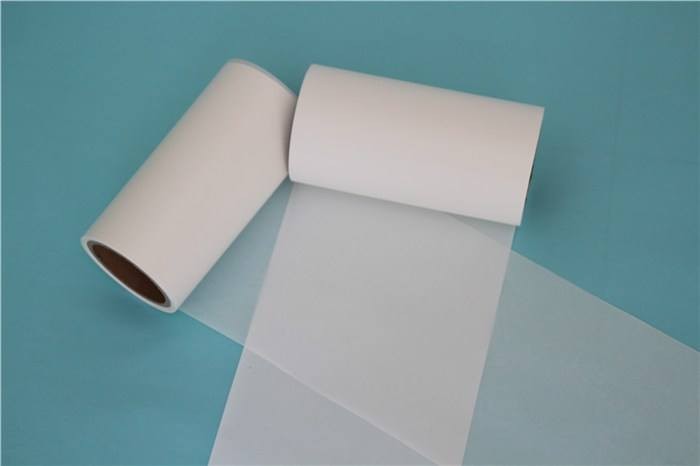

Release paper, also known as silicone paper, anti sticking paper. It is mainly used to isolate sticky objects, such as adhesive tape. When used, it usually needs to be stripped and discarded. At present, it is mainly used as the carrier of adhesive tape or adhesive tape products. This paper introduces the main classification of silicone paper.

Release paper is produced by coating the base paper with release agent on the surface of the coated film.

Because there are paper hairs and fibers on the surface of the paper, the film must reach a certain amount to ensure that there is no penetration point, that the silicone oil will not penetrate into the paper, and that there will be no bad peeling. Generally speaking, the amount of coated paper is 16 grams per square meter. But in theory, as long as the tape can be stripped from the top, no matter how low the film amount is.

It is divided into single drench and double drench. Generally speaking, one side is single coated, of course, there is also one side of double coated, because the thick coating on the release surface is generally 20g, while the thin coating on the non release surface is generally 15g, so the release paper is relatively flat. If it is a double-sided coated paper with 22 grams of coated film, it is more suitable for making double-sided.

It generally uses whole wood pulp paper. If straw pulp paper is selected, there will be a lot of paper scraps during die cutting, which is easy to break the edge. All wood pulp paper is generally called kraft paper, such as natural kraft paper (commonly known as Benniu), white kraft paper (commonly known as Bainiu), yellow kraft paper (commonly known as Japanese yellow colored cow) and blue kraft paper (commonly known as Indonesian blue colored cow). Of course, there are also all wood pulp double offset paper as base paper, photographic paper as base paper, coated paper, whiteboard, cow card, milk card and other papers as base paper.

As long as the plastic fastness of the coated paper can meet the requirements, as long as the coated film has no penetration point and the coated film is uniform and flat, any paper can be used as base paper.

Release paper is produced by coating release agent on grasin base paper after overpressure.

Because grasin is super calendered, the paper is very tight.

The paper has the characteristics of high temperature resistance, moisture resistance and oil resistance.

CCK base paper is a release paper produced by coating a layer of special clay on the surface and then coating release agent.

Because of its excellent high temperature resistance, it has been widely used in carbon fiber industry.

The clay on the surface of CCK base paper is very easy to destroy silicone, so few cckrelease papers produced in China can really meet the standard.

In addition, some release papers are widely used in many industries, and some of them do not use release agents. For example, some manufacturers usually apply a layer of varnish to the places where release is required, which will also have a certain release ability, but the performance of the glue is very weak. Otherwise, this release capability is also reactive. Others are produced with special glue and other formulas, accounting for a small market share.

At present, with the development of society, release paper is widely used in social life. Understanding the main categories of silicone paper will help people better use it.

Comment(0)

You can comment after

SIGN IN