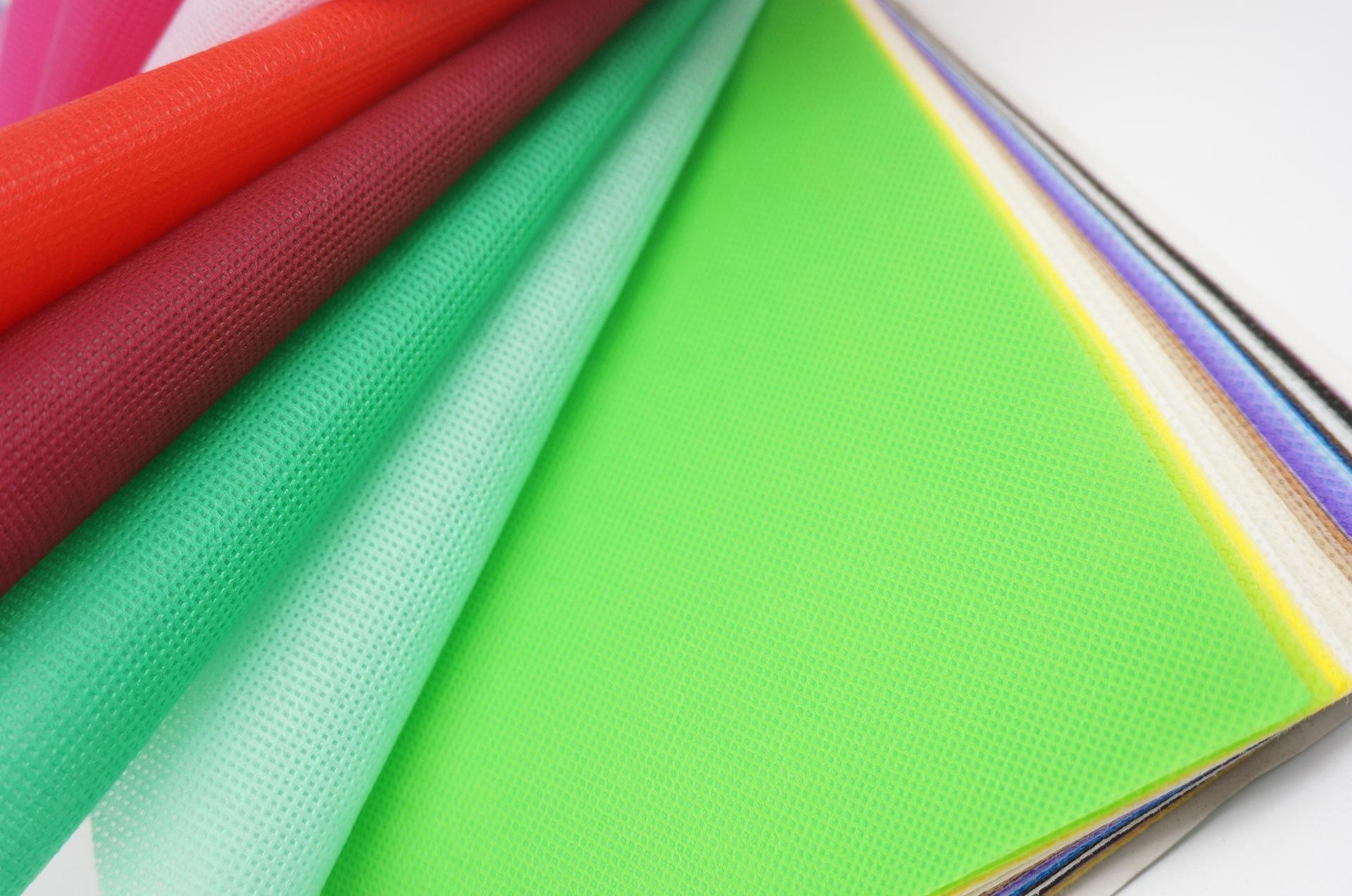

At the initial stage of development, the construction of China's spunbond non woven fabric production line was mainly modeled on developed countries. The internal quality of the product is very good, and the uniformity of nonwovens can also be effectively reflected. However, the actual surface quality of nonwovens is limited, and the fiber strand problem is particularly serious, which reduces the production quality of the whole production line. Generally speaking, in addition to fiber strand caused by poor sudden cooling of cold air during spinning, three other situations are involved. According to the previous work experience, this paper discusses the solution to the fiber strand problem in the spunbond non woven production line from three aspects: the fiber strand of the nozzle Gallery, the fiber strand of the wire pendulum, and the fiber strand of the screen curtain of the screen forming machine.

It can be seen from the previous work that the fiber strand in the nozzle Gallery of the spunbond non woven fabric production line is easy to find. When the tow passes through the spinneret, the tow will be evenly distributed. However, before entering the nozzle, if the fiber distribution is uneven, the staff can confirm that there is a fiber strand problem in the nozzle, which can also occur at the nozzle outlet. In order to avoid the fiber strand problem in the nozzle, the staff need to control the size and accuracy of the nozzle throat to keep the actual situation synchronized with the design requirements. In addition, during the production process, the spinneret shall be prevented from leaking or breaking wires, so as to reduce the probability of material dripping into the nozzle channel. In practice, silicone oil spraying is essential, but the spraying amount should be as low as possible. It is also necessary for actual gaseous materials to enter the nozzle gallery. For this problem, people can use monomer suction device to solve it. In addition to the above operations, the manager should also formulate equipment maintenance and maintenance plans according to the actual situation, such as regularly cleaning the inner wall of the nozzle, so as to reduce the probability of fiber strand problems.

When spunbond Non woven fabric production line in the nozzle of the spunbond silk and air flow into the swing piece together, the upper end of the swing piece can achieve real hinged fixed. At this point, airflow will form between the two metal walls and flow through the channel. The beam wire can also swing with the swing of the pendulum plate, avoiding the problem of cross wires of circular roller ator and reducing the probability of fiber strand. More importantly, the actual size of a reciprocator must be properly controlled. If the size is too large, the tow will shrink inward in the width direction. If the size is too small, the strands will expand outward along the width, resulting in a new fiber strand problem.

In order to balance the air volume above and below the net curtain, the suction volume of the fan in the air conditioning room can be increased. Among them, the amount of air inhaled mainly includes the amount of air ejected from the nozzle, as well as the air supplement on the screen curtain behind the screen machine and the air supplement on both sides. The latter air supplement form is very easy to cause the problems of floc turning over and flanging. Therefore, in actual operation, the staff can divide the main air duct of the screen laying machine into several units, adjust the pressure respectively, and add two heating pre pressing rollers on the main air duct and auxiliary air duct to avoid fiber strand, screen turnover and flanging on the screen curtain. When the wadding is pressed, it is not easy to turn over the net and turn over the edge, just like being ironed. It can also improve the surface quality of spunbond non woven fabric, help relevant enterprises obtain higher production speed and improve economic benefits.

To sum up, in order to solve the fiber strand problem in the spunbond non woven fabric production line, relevant personnel should carry out targeted research work, clarify the precautions in the operation of the production line, and adopt targeted solutions to reduce the probability of fiber strand problem in the spunbond non woven production line.

Comment(0)

You can comment after

SIGN IN