Since the outbreak of the epidemic, enterprises have responded to the call of the government to switch to production of masks and other epidemic prevention materials, and the production capacity of masks has been greatly increased. However, consumers generally report that they still can not buy masks, and masks are still in a difficult situation. Why can't people buy masks? Today, let's take you to understand one of the key factors restricting the production of masks: meltblown fabric.

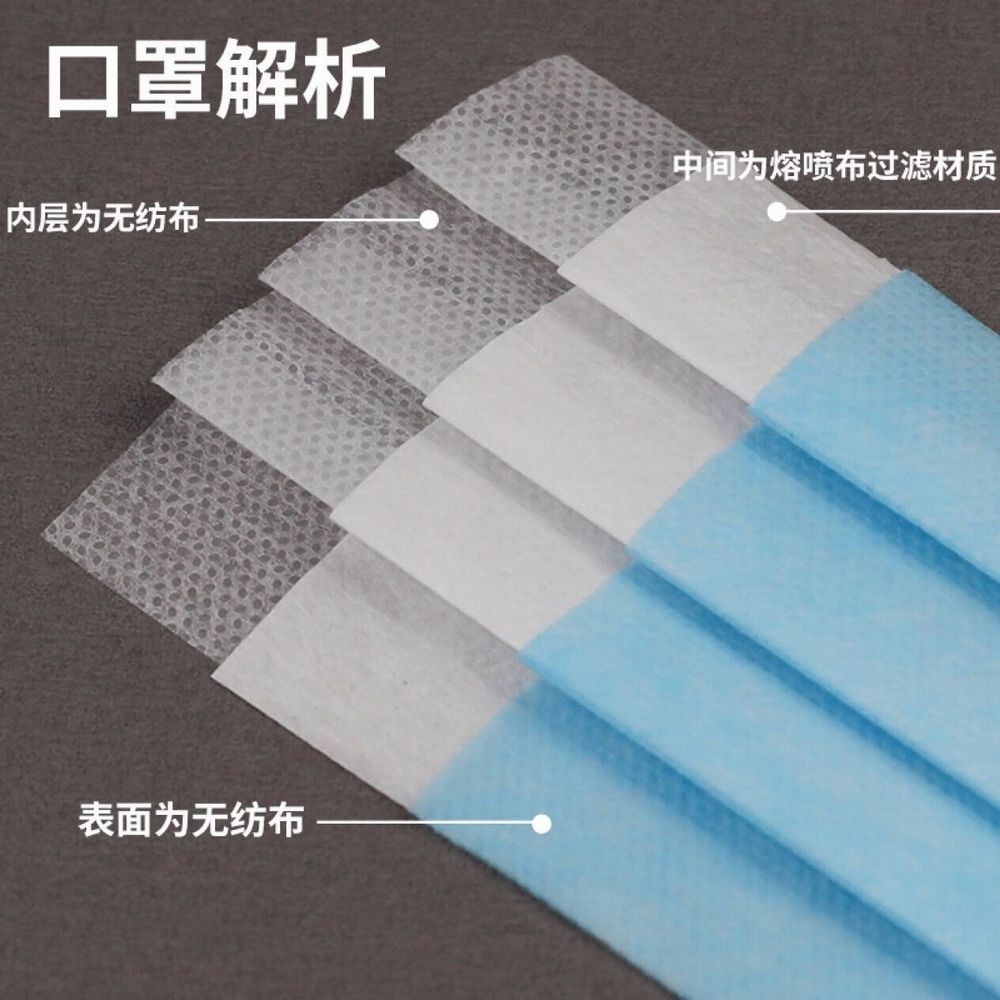

When we cut the medical mask with scissors, we can see that the mask is divided into three layers: internal absorbent layer, intermediate filter layer and external waterproof layer. The inner layer is a skin friendly hygroscopic layer (spunbonded non-woven fabric material, mainly used for hygroscopic), the middle layer is an isolation filter layer (made of electret treated meltblown fabric material, mainly used for blocking bacteria, viruses and small particles), and the outer layer is a spunbonded water repellent layer (spunbonded non-woven fabric material, mainly used for blocking droplets). Through the different materials and properties of the three-layer materials, we can clearly understand that the isolation filter layer in the middle plays a decisive role in blocking bacteria, viruses and micro particles, and the material of the isolation filter layer is meltblown non woven fabric.

Meltblown fabric, commonly known as the "heart" of masks, is a film made of polypropylene with high melt index, which is randomly stacked by many crisscross fibers. The fiber diameter range is 0.5-10 microns, about one thirtieth of the hair. Although the size of novel coronavirus is very small, about 0.1 μ m, which seems to be smaller than its fiber diameter, do not forget that the virus cannot exist independently. Its transmission route is mainly secretion and sneezing droplets, which are about 5 μ m in size. It is essentially a fiber filter. When the droplets containing virus approach it, they will be electrostatic adsorbed on the surface and cannot pass through, thus playing the role of virus isolation.

Since meltblown fabric is very important, can enterprises improve their production capacity? The answer is: it's not that simple. It is understood that due to the long lead time of production equipment and high technical requirements for personnel operation, its production capacity is difficult to be rapidly improved in a short time. There are not many large manufacturers that can produce in China, and the whole industry presents a small and scattered situation. The industry was lack of attention before, and has been showing a tepid trend. Its production principle is clear, but the actual production process is relatively complex, involving disciplines such as polymer science, fluid mechanics, airflow, spinning, etc., and the requirements for equipment manufacturing are relatively high. The price of production equipment often exceeds 1million yuan, and special training is also required for employees, so the threshold of the industry is high. The supply cycle of foreign manufacturers is as long as 8 months, and that of domestic manufacturers is more than half a year. Key components are imported. Many factors, such as long cycle, high cost, high industrial threshold and high income risk, have become the main reasons restricting its market expansion.

The number of meltblown fabrics is limited, and the number of meltblown non woven fabrics that meet the medical standards is even less. As a result, the current cloth merchants bid up prices, making the original price of about 20000 yuan / ton soar. The current statistics show that it has reached 300000 yuan / ton, an increase of 15 times, and has to be snapped up in many ways. This is a key factor for the rising price of finished masks and limited production capacity.

With the development of the epidemic, meltblown fabric, as the "heart" of the mask, has also received extensive attention. If we want to break the difficult dilemma of "one cover", we must also solve the problem of meltblown non woven fabric.

Comment(0)

You can comment after

SIGN IN