Since the "SARS" in 2003, the market of medical protective materials in China has developed rapidly. According to the basic functions, it can be roughly divided into two types: reusable and disposable. The former is mostly traditional textile products, and the latter generally refers to nonwovens. Among nonwovens, SMS non woven fabric has developed rapidly. This paper discusses the use of raw PP in SMS non woven and the method of functional modification.

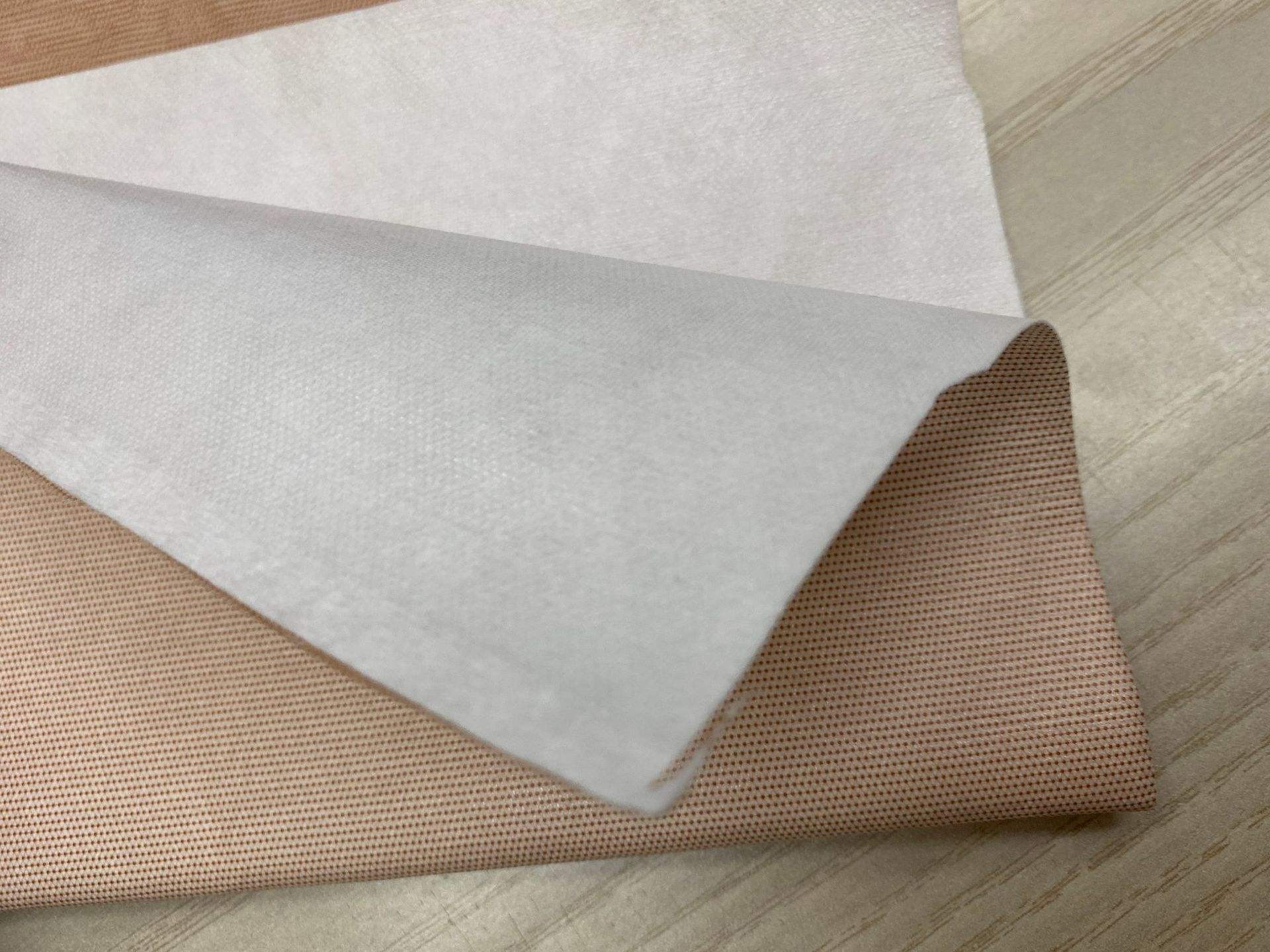

At present, PP is still the most used raw material in SMS non woven fabric products. The surgical suit is usually made of PP chips by melt spinning.

In order to develop medical supplies with special functions such as shielding, softness and health care, substances with special functions can be added when preparing polymer chips. For example, functional masterbatch is added in the process of polymer slicing, so that the product has the functions of heat preservation, health care, antibacterial, deodorization, etc., and is more suitable for medical and health care.

PP modification generally includes physical modification and chemical modification. Physical modification refers to adding other substances through reinforcement, filling, blending and other methods to make it have new functions; Chemical modification refers to changing the internal molecular structure of PP by grafting, copolymerization and cross-linking, so as to achieve the purpose of changing the properties. From the production process of SMS non woven fabric products, the method of physical modification of PP to endow it with functionality is very suitable for industrial production.

The melting point, softening point and glass transition temperature should be considered in the functional modification of PP chips, and its rheological properties should be analyzed. In the process of polymer melting, with the increase of temperature and melt flow rate, the shear viscosity of the melt decreases, and the shear stress on the polymer melt decreases, so the fiber diameter decreases. Generally, when preparing functional chips, substances that reduce the melting temperature of the polymer will be added to reduce the fiber diameter, unevenness and crystallinity. At the same time, the spinning temperature can be reduced by 20 ~ 30 ℃.

Add different kinds of functional masterbatches according to the requirements of the final product. The raw materials of functional masterbatch generally include resin carrier, dispersant and functional additives. The raw materials are fully and evenly mixed in the high-speed mixer, extruded by the screw extruder, cooled, sliced and granulated to obtain the functional masterbatch. The applicable functional masterbatch includes anion masterbatch, color masterbatch, antibacterial and deodorizing masterbatch, soft masterbatch, etc.

At present, the disposable protective textiles used in medical institutions in China have the problems of low proportion and low quality, which are easy to cause postoperative infection, cross infection and repeated infection. The unique performance of SMS non woven fabric products makes it develop rapidly in the medical and health industry, and has the trend to gradually replace the traditional medical protection products. The functionalization, softness and comfort of SMS products and ultra-fine fiber are the important development directions of the industry at present. Starting from the modification of raw materials, further optimization of process parameters will greatly promote the development and application of SMS non woven medical products.

Comment(0)

You can comment after

SIGN IN