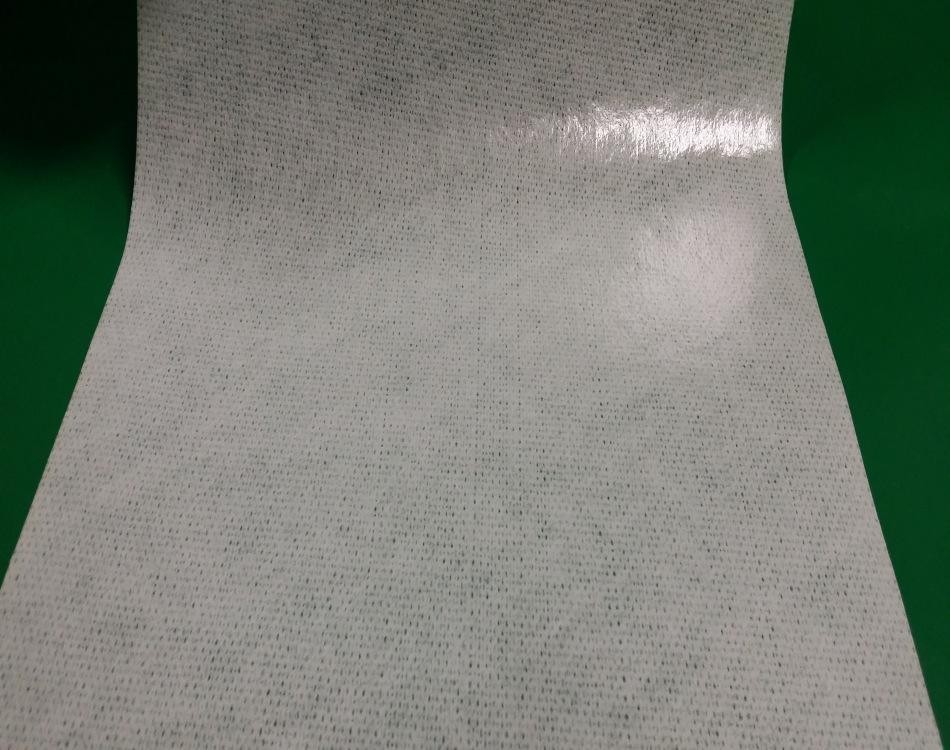

In the domestic disinfection supply center, except cotton cloth, the most commonly used packaging material is non woven fabric. When selecting non woven, hospitals usually pay more attention to thickness, that is, gram weight. Is it the thicker the better? The answer is No. Here are the reasons why it is not the thicker the better.

The increase of the thickness of non woven fabric means that the weight per unit area increases and the corresponding strength increases. However, due to its own structural characteristics, the increase of thickness does not mean the increase of microbial barrier performance. For example, if the thickened non woven is used, the increase in the weight of its adhesive layer cannot effectively improve its antibacterial performance. Only when the pore diameter of key filter layer (i.e. melt blown layer) can effectively filter microorganisms and dust, its antibacterial performance can meet the requirements. With the increase of thickness, the air permeability of packaging materials will also be affected, and the possibility of wet package phenomenon will also increase.

In clinical practice, non woven fabric will be damaged after sterilization. For this breakage phenomenon, the main reason is that after high-temperature sterilization, the micro plastic fiber will shrink to a certain extent. The performance in use is that it is more brittle after sterilization than before sterilization. Therefore, if excessive force is applied or unreasonable taking and placing methods are used in the process of use, the packaging materials will be damaged. In addition, the use of instruments with burrs and sharp edges will also cause breakage. In this case, it is recommended that the clinic should maintain proper tightness during the packaging process, handle it carefully, and use the double-layer packaging recommended by the standard, which will greatly reduce the possibility of breakage. If the breakage problem is solved only by increasing its thickness, in addition to ensuring antibacterial performance, it is also necessary to closely observe the possibility of wet bags.

In short, the thicker the non woven fabric, the better. On the premise of ensuring antibacterial property and tensile strength, only materials with good air permeability can reduce the wet package phenomenon of non woven.

Comment(0)

You can comment after

SIGN IN