S is single layer spunbond non woven fabric and SS is double layer spunbond non woven fabric, so what is the difference between them?

Traditional softness can distinguish between S and SS.

S spunbond non woven fabric is mostly used in the packaging field, SS spunbond non woven fabric is mostly used in sanitary materials. Therefore, in the mechanical design, the S machine tends to stiffen the non woven fabric, while the SS machine tends to soften the non woven fabric.

However, after a special process, S spunbond non woven fabric is softer than untreated SS fabric and is suitable for hygienic materials; SS can also be hardened and is suitable for packaging materials.

Another difference latitude is the uniformity of the cloth, which is the stability of gram weight per square meter, but it is difficult to distinguish with the naked eye.

The essence of the difference between S and double SS is the number of machine nozzles, the number of letters represents the number of nozzles, so S a nozzle, SS two nozzles.

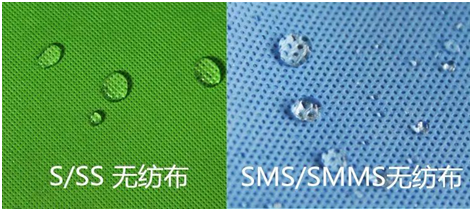

Hot-rolled by two layers of fiber mesh, the finished product is non-toxic and odorless, with high isolation efficiency. Anti-static, anti-alcohol, anti-plasma, anti-water and other properties can be processed by special equipment and process.

Spunbond non-woven fabric, the main materials are polyester and polypropylene, high strength, good high temperature resistance Spunbond non-woven fabric: polymer extrusion, stretching, forming continuous filament, filament laying into a net, fiber network through its own bonding, thermal bonding, chemical bonding or mechanical reinforcement methods, so that the fiber network becomes a non-woven fabric.

SS spunbond non-woven fabric is softer than other non-woven products.

It uses polypropylene as the material, which makes up a low percentage of the total. It has a better fluffiness than cotton and is skin-friendly to the touch. It is skin-friendly because it is soft and consists of many fine fibers.

All products made from fine fibers are highly breathable, keep the fabric dry, and are easier to wash. It is a non-irritating, non-toxic product that meets the requirements of food-grade ingredients without any added chemicals and is not harmful to the body.

It has unique antimicrobial properties, does not produce moths, isolates bacteria and parasites from internal fluids, and the antimicrobial properties make this product widely used in healthcare.

Some textile fibers and filaments are fixed by thermal bonding or chemical methods. By special treatment of equipment, antistatic, alcohol, plasma, water and water production properties can be achieved.

Features of spunbond nonwovens: Durable, disposable. Insulating, conductive. Soft, rigid. Fine, swell. Filtering, breathable, impermeable. Elastic, stiff.

Light, loose, warm. Thin as cicada wings, thick as felt.

Waterproof and moisture permeable. Ironing, sewing, molding. Flame retardant, anti-static. Water permeable, waterproof, abrasion resistant, pile. Wrinkle resistant, good elasticity, high moisture absorption, water resistant.

Due to this special function has been widely used in the fields of textile and clothing, decoration materials, medical and health materials, etc.

It is suitable for the production of baby diapers, diapers, sanitary napkins, adult diapers, hospital hygiene products (sanitary pads, masks, protective clothing and other non-woven fabric series), and to improve the quality stability of finished products.

Both SS spunbond non woven fabric and S spunbond non woven fabric are indispensable in their respective fields, and they will be involved in more and more fields as non woven processing technology advances.

Comment(0)

You can comment after

SIGN IN