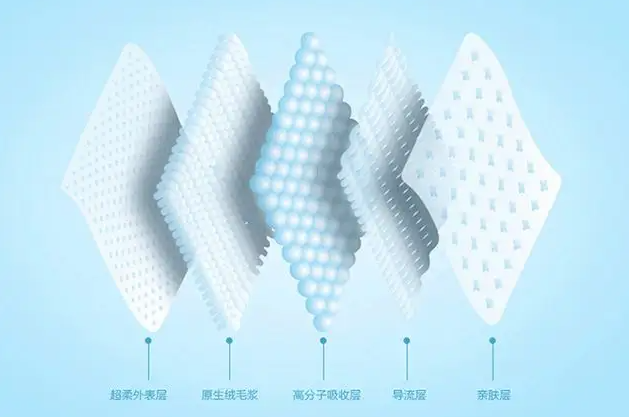

Breathable film is a necessary material for diapers. The structure of diapers is divided into three layers: surface coating, absorbent core layer and bottom layer. The surface of the diaper is made of non-woven fabric, the absorbent core layer is absorbent beads and fleece fiber, and the bottom layer material is mainly made of PE film or PE film + non-woven fabric. breathable PE film's main purpose is to prevent urine leakage.

breathable film generally refers to PE functional material with environmental protection, waterproof and breathability. It is mainly used for female sanitary napkin bottom film, pad bottom film, baby diaper bottom film, etc. Laminated with non-woven fabric, it is also widely used in medical protective clothing, isolation clothing, medical mattresses, disposable bedding, home textile products, etc. In addition to its own material function, the process is also very important to whether the breathable film is breathable or not.

(1) Extended composite material. This process is a sticky composite material made from plastic particles that have been hot-melted to the plastic itself. The disadvantage is that it is almost impermeable to air. 2014, there is no way around the world to produce a truly highly breathable, heat-resistant waterproof breathable film with this process.

(2) Spray glue or scratch glue composites. This process was originally applied to sanitary napkins, diapers and protective clothing. At present, almost all domestic manufacturers use this process to produce highly breathable waterproof breathable materials. The disadvantage is that the breathability is relatively low because the intermediate micropores are actually blocked by the hot melt adhesive. In addition, the most fatal disadvantage is the very low temperature resistance, which can only withstand a temperature of 60 degrees. Because of this adhesive. Because this adhesive is actually a pressure-sensitive adhesive (self-adhesive). A simple example is that in winter, the double-sided tape has almost no viscosity and will delaminate, but in summer, the glue on the surface of the double-sided tape will melt. One can imagine the quality of the manufactured waterproof breathable film. Therefore, this kind of waterproof breathable film can only be counterfeit products, and there is no market in Europe and America.

(3) Hot pressing composite materials. At present, the domestic market is mixed, the production of real waterproof breathhable film manufacturers are actually very few. In fact, the real waterproof breathable film should be highly breathable, high temperature resistance, aging resistance, hydrostatic pressure of more than 2 meters. The production process should be pure thermal compounding technology without glue, which can reach a temperature resistance of more than 110 degrees and high strength anti-aging, which is the latest technology in China that can really meet the EU standards.

The main determining factor of breathable performance is the number of breathable holes in the breathable base film and the manufacturing process. The main thing to pay attention to is the colloid, including the diaper adhesive and structural adhesive.

Although the amount of structural adhesive used in diapers is not large, the selection of high quality structural adhesive and breathable film and other raw materials ensures high quality diapers, which is beneficial to the safety, health and comfort of infants and children.

Comment(0)

You can comment after

SIGN IN