In order to better, correctly and safely use familiar operation tampon equipment, reduce equipment failures, ensure that equipment and facilities are in good condition, stabilize product quality for a long time, ensure normal operation of equipment, and ensure product quality and quantity. Next, let's introduce the faults of tampon machine.

Due to the use of speed regulating motor, the structure of tampon equipment main axle box is relatively simple. The parts prone to failure are the tool automatic clamping mechanism and automatic speed regulating device in the main shaft. The automatic clamping mechanism adopts spring clamping, and is equipped with a travel switch to send a clamping or loosening signal, so as to ensure that the tool will not be loosened in vain during work or power failure. If the tool cannot be loosened after clamping, consider adjusting the pressure of the tool loosening hydraulic cylinder and the travel switch device or the nut on the disc spring to reduce the pressure of the spring. In addition, spindle heating and spindle box noise should not be ignored. At this time, it is mainly considered to clean the spindle box, adjust the lubricating oil quantity, ensure that the spindle box is clean, replace the spindle bearing, repair or replace the spindle box gear.

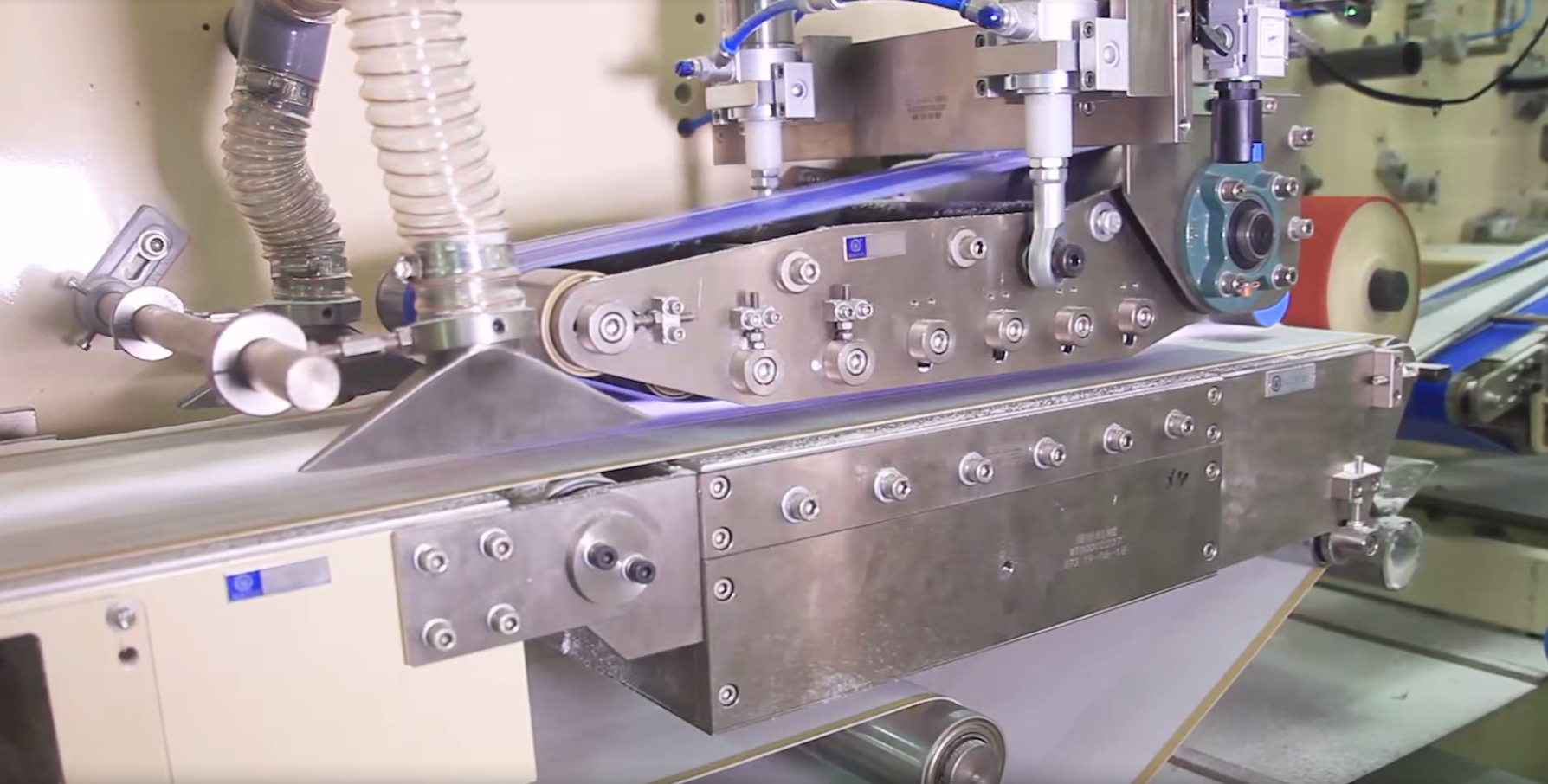

Tampon equipment transmission system is commonly used in ball screw pair, hydrostatic screw nut pair, rolling guide rail, hydrostatic guide rail and plastic guide rail. Therefore, the failure of the feed transmission chain mainly reflects the decline of the motion quality. For example, the mechanical parts do not move to the specified position, the operation is interrupted, the positioning accuracy is reduced, the reverse clearance is increased, crawling, bearing noise is increased (after the crash), etc. The following measures can prevent such failures:

(1) Improve transmission accuracy. Adjust the preload of the motion pair, adjust the loose links, eliminate the transmission gap, shorten the transmission chain, and set the reduction gear in the transmission chain to improve the transmission accuracy.

(2) High transmission stiffness. The effective measures to improve the transmission stiffness are to adjust the pre tightening force of the nut pair and the supporting parts, and to reasonably select the size of the screw itself. Insufficient stiffness will also lead to creeping vibration of the workbench or carriage, resulting in reverse dead zone and affecting the transmission accuracy.

(3) Improve motion accuracy. On the premise of meeting the strength and stiffness of components, the mass of moving components and the diameter and mass of rotating components shall be reduced as far as possible, so as to reduce the inertia of moving components and improve the motion accuracy.

(4) Guide rail. The rolling guide rail is sensitive to dirt, so it must have good protective devices. The preload of the rolling guide rail should be properly selected, and the excessive meeting can significantly increase the traction. The hydrostatic guide rail shall have a set of oil supply system with good filtering effect.

The faults of automatic tool change device of tampon equipment mainly include: motion fault of tool magazine, excessive positioning error, unstable mechanical handle, excessive motion error of manipulator, etc. A serious fault will cause the tool change to get stuck and the machine will be forced to stop working.

Secondly, it depends on the degree of intelligence of the equipment. There are very few places where the equipment with a high degree of intelligence needs to be manually adjusted, because the fewer places the equipment needs to be manually adjusted, the fewer problems will be. The degree of intelligence of the machine is mainly reflected in the touch screen.

In fact, what we said above is only what we need to pay attention to when we are preparing to order. There is a problem with the equipment. Manufacturers with professional after-sales teams don't need customers to worry, because this is after-sales work, which can be solved by phone and video. The after-sales personnel couldn't come to solve the problem free of charge. In short, choosing a manufacturer with good after-sales service and reliable quality is to save a lot of unnecessary trouble in future production.

Comment(0)

You can comment after

SIGN IN