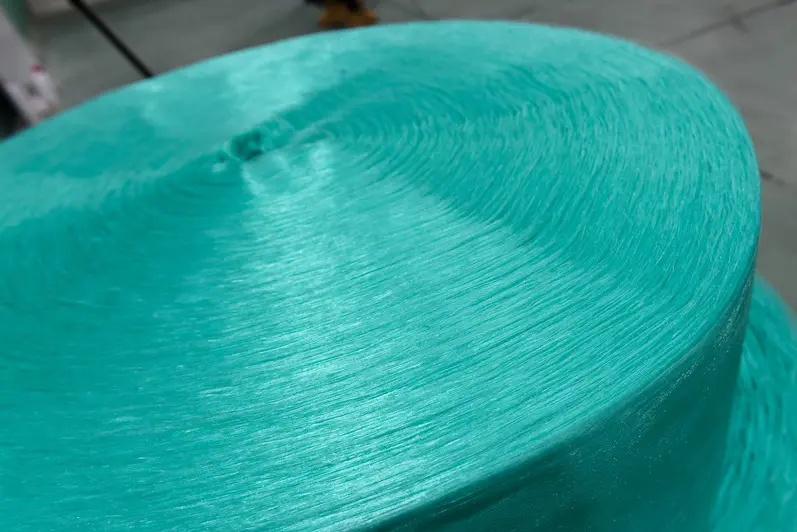

As the main accessories of pull-ups and toddler pants products, the quality and performance of non-woven materials directly determine the quality and performance of the products. Textile nonwovens include textile bonded nonwovens, meltblown nonwovens and composite materials, which not only have high production capacity, low price and stable performance; the water repellency of raw polypropylene (PP)/polyethylene (PE) itself, Water permeability and non-water retention make it a key position in pull-ups products.

The main function of the pull-ups surface is to quickly guide the urine absorbent core and keep it dry[. Polypropylene, the raw material for textile melted nonwovens, has zero water absorption. After using hydrophilic oil tissue, it has the property of quickly penetrating liquid without absorbing water. According to the finishing process, by adjusting the relative speed between the textile melted nonwoven fabric and the coating edit, textile melted nonwovens with different oil content can be obtained.

As the oil content of the nonwoven fabric increases, its liquid penetration time shows a decreasing trend and the trend slows down. But when the oil content of the non-woven fabric increases to 1.2%, the phenomenon of hydrophilic oil transfer occurs. If there is hydrophilic oil transfer on the surface, pull-ups will contaminate the anti-side leakage partition, reducing the anti-hydrostatic pressure performance of the anti-side leakage partition, thereby reducing the risk of pull-ups side leakage. Therefore, the spun melt nonwoven fabric after the hydrophilic oil finishing should not only have good liquid penetration, but also prohibit the transfer of hydrophilic oil. Experiments show that for most hydrophilic oils, the oil content of spun melt nonwovens is best controlled within 07% to 1.0%.

The tensile strength of SSS mesh spunbond nonwovens is better than that of SS mesh spunbond nonwovens, but the softness is slightly worse, mainly because the fiber web of SS mesh is more uniformly distributed and the fibers are thinner. Reducing the adhesion between fibers of nonwovens can significantly increase the softness and loft of the product and improve the feel of the product, but it also loses the tensile strength of the product because the adhesion between fibers in the fiber web is reduced. In the production of textile fused nonwovens, optimizing the material configuration can also significantly improve the feel of the product, increase the softness and bulk of the product, but also lose the tensile strength of the product; the main reason is the performance difference between materials, That is, adding a certain proportion of functional materials to polypropylene naturally reduces the tensile properties of polypropylene. But at the same time, functional materials perform their functions in the product and improve the product style.

As a material that directly contacts the skin, the surface layer needs to be soft and breathable, so that urine can penetrate quickly, absorb almost zero water, and keep it dry close to the skin. Hydrophilic spunbond nonwovens can well meet the requirements of the surface layer. The spunbond nonwovens used in the surface layer are mostly SS (double-layer composite spunbond nonwovens)/SS (three-layer composite spunbond nonwovens) products with hydrophilic tissue, and the gram weight is mostly 13~23g/m2. Adult pull-ups surface layer generally does not require deep processing, and the gram weight is mostly 13~15g/m3; infant pull-ups and toddler pants surface layer will undergo different degrees of deep processing such as punching, embossing, and embossing according to the degree of product differentiation. In order to obtain a strong 3D sense, the gram weight is mostly 17~23g/m2.

Comment(0)

You can comment after

SIGN IN