According to CNITA statistics, in 2021, my country's nonwoven production will be 8.205 million tons, a year-on-year decrease of 6.6%, but compared with 2019, the two-year average growth rate will be 14.83%, proving that my country's nonwoven production has grown steadily.

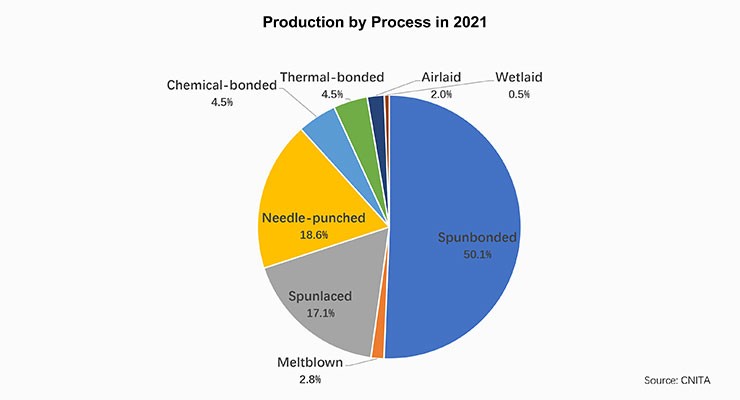

Spunbond, needle punched and spunlace are the main non-woven fabric processes in my country, accounting for 85.8% of the total. Production of spunbond nonwovens fell 10.5% to 4.108 million tons due to lower demand for anti-epidemic materials. However, the output of polyester spunbond nonwovens for engineering materials increased by 20.6% to 679,000 tons. In 2021, the recovery of China's construction, automobile, and environmental protection markets stimulated the demand for needle-punched nonwovens, which increased by 6.5% to 1.523 million tons. Production of spunlace nonwovens increased by 7.7% to 1.4 million tons.

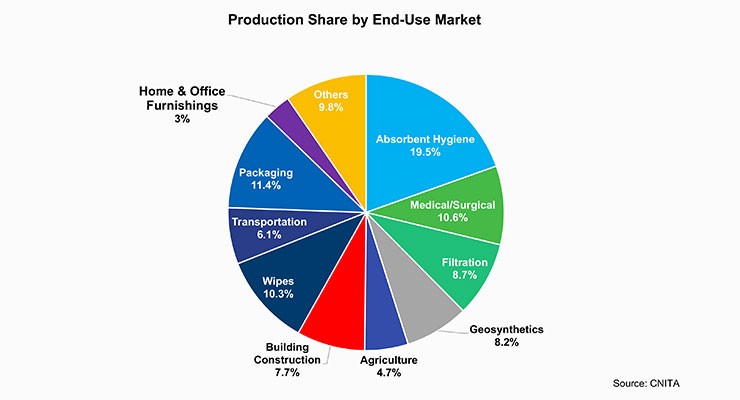

With the sharp drop in the demand for masks in domestic and foreign markets, most of the newly added meltblown nonwoven production capacity in 2020 will withdraw from the market in 2021, and China's meltblown nonwoven production will drop by 57.1% to 233,000 tons. End-use markets, absorbent hygiene materials, medical and surgical materials, wipes, geosynthetics, construction, packaging, filtration and transportation are the main application areas for nonwovens in China.

Absorbent hygiene products such as baby diapers, sanitary napkins and adult incontinence products are the largest end use of nonwovens, accounting for 19.5% of nonwovens applications in China. Despite the significant drop in demand for masks and protective clothing in 2021, medical surgical nonwovens still account for 10.6% of the total market. Wet wipes are a fast-growing application area for nonwovens, accounting for 10.3% of the market share. Packaging, filtration, geosynthetics, building construction and transportation accounted for 11.4%, 8.7%, 8.2%, 7.7% and 6.1% of the market, respectively.

Regarding the nonwovens investment in nonwovens last year, Ji Jianbing, vice president of industry research at the China National Trade Research Council, said, "The investment in new production capacity is mainly concentrated in intelligent manufacturing and environmentally friendly products. Some polypropylene spunbond, needle punched nonwovens The successful installation and commissioning of the production line for woven fabrics, wood pulp-based spunlace or meltblown nonwovens and put into operation will further optimize the structure of my country's nonwovens industry."

Talking about the development environment of China's nonwovens, Li Guimei, president of China National Textile and Apparel Industry Association, said, "The factors that promote the development of China's nonwovens industry will not change. The implementation of strategies such as expanding domestic demand, ecological protection and environmental protection, and healthy China 2030 will not change. Promote the development of the nonwovens industry.”

"China's nonwovens industry will continue to implement the new development concept of innovation, coordination, green, openness and sharing, and adhere to the development direction of high-end, digital and green development, and ensure the sustainable and high-quality development of the industry." She added.

Comment(0)

You can comment after

SIGN IN