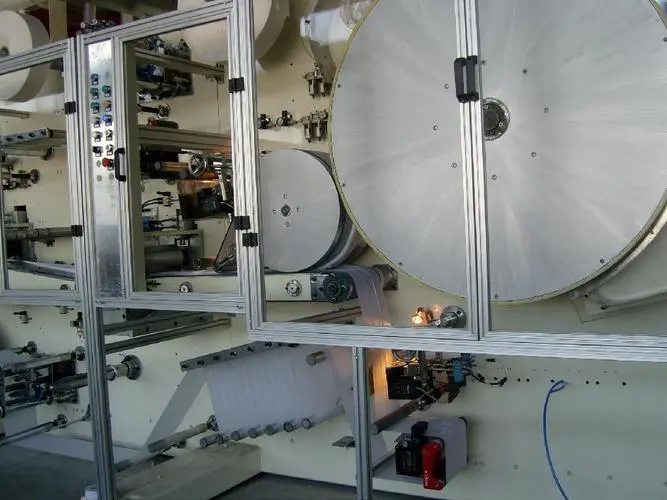

Maintenance technology occupies an important proportion in the automatic baby diaper machinery, and plays a key role at the same time. Combined with the application of maintenance technology in equipment and analyzing the current situation, we can effectively plan the future development, give full play to the advantages of maintenance technology and meet the operation needs. The fully automatic baby diaper machine has the characteristics of systematic and cumbersome. Affected by the operation, it increases the difficulty of maintenance technology and is easy to cause wrong operation. The automatic mechanical maintenance technology of baby diapers should be developed to the following needs.

All operations of maintenance technology should develop in a stable direction, and promoting stability has become the basic need for the development of equipment maintenance technology. It is helpful to prolong the service life of the equipment and reduce the demand for maintenance through the application of technology. Take stability as a demand in the development of maintenance technology, meet the own needs of configuration, and ensure the efficiency and quality in the operation of maintenance technology.

There are certain risks in maintenance, such as power on risk and mechanical risk. Therefore, in the process of promoting the development of repair technology, requirements should be put forward in terms of safety to make maintenance personnel aware of the importance of safety maintenance. In terms of repair technology, put forward safety requirements, control various behaviors and operations of maintenance personnel, and urge maintenance personnel to strictly follow the safety regulations and not repair without permission. On the one hand, protect the safety of equipment and on the other hand, protect the safety of maintenance personnel. For example, in the repair technology of equipment containing circuits, technicians need to complete the operation in the case of power failure. Even if the power on hazard is small, they can not operate with power on, so as to meet the safety requirements of maintenance technology in an all-round way.

The operation management equipment is responsible for the daily maintenance, inspection, monitoring, diagnosis, repair, update and other management of all equipment, including the prevention of equipment performance degradation. Its purpose is to ensure that the equipment is often in good technical condition during operation and effectively reduce the maintenance cost.

Preventive maintenance is the demand of equipment maintenance technology in many industries, and equipment maintenance is also introduced to prevent faults in the maintenance cycle, reduce the number of post maintenance, emphasize the initiative of future development of maintenance technology and minimize the proportion of passive maintenance. With the development of, the preventive demand of maintenance technology is increasing, mainly to improve the working efficiency of the equipment and prevent its failure during operation.

Maintenance technology plays a more and more important role in equipment operation, which is directly related to the production efficiency of the industry. According to the development needs of machine repair technology, the current situation of repair technology should be clarified. On this basis, speed up the development of repair technology, keep up with the progress of the industry, and then meet the operation needs of the machine. Through the development of maintenance technology, the fully automatic baby diaper machinery industry needs to provide effective basic support to eliminate the potential safety hazards of the equipment. Improvement and maintenance refers to the continuous use of advanced process methods and technologies to correct some defects and inherent deficiencies of the equipment, improve the stability, safety and prevention of the equipment, and improve the utilization rate of the equipment.

Comment(0)

You can comment after

SIGN IN