The penetrability test of thickened sanitary napkins is a part that all production companies need to conduct sampling self inspection to ensure that the products produced are of high quality. Let's see what the standard moritou performance test steps stipulated by the state are.

① One set of thickened sanitary napkin permeability tester

② One balance: measuring range 200g, sensitivity 0.0lg

③ A steel ruler

④ Special standard test solution for the permeability of thickened sanitary napkins

① Instrument adjustment and installation: place the penetrameter on a horizontal plane and adjust the angle between the upper plate and the lower plate by about 10. Angle, adjust the distance between the vertical projection point of the lower opening of the drain funnel and the lower edge of the upper plate (inclined panel) to be (1404-2) mm, the lower end of the lower opening of the funnel is about 5 to 10 mm from the sample surface, and the opening surface of the lower opening shall be placed outward. Place a beaker under the inclined panel to catch the leaking solution.

② First wash the funnel with an appropriate amount of test solution, and then discharge the solution in the funnel after washing twice. Take one sample to be tested, weigh its strip mass (accurate to 0.01g), and then place it on the inclined panel of the penetrameter flatly. The lower edge of the effective length of the sample (referring to the lower edge of the inner absorption layer) is aligned with the lower edge of the inclined panel, and part of the growth is folded back to the bottom of the lower edge of the inclined panel. Press the standard test net evenly and symmetrically on the sample. If the sample is seriously folded and cannot be placed horizontally, remove the anti sticking release paper behind it, and then gently stick the sample to the inclined panel. After the test, paste the release paper back and weigh it together.

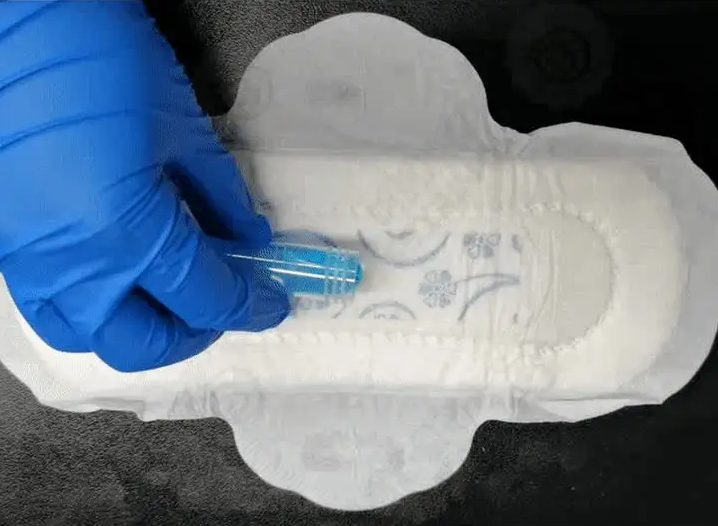

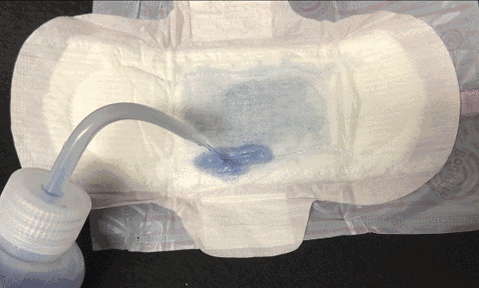

③ Use a pipette to accurately transfer 5ml of test solution into the discharge funnel, quickly open the funnel valve to the maximum, so that the solution can flow freely to the surface of the sample and flow downward along the inclined plane of the upper plate. After the solution flows, close the funnel valve, gently press down the standard test net, remove the net, then pick up the sample, gently touch the lower mouth of the funnel, absorb the residual solution, and put the sample on the balance for weighing. If the solution flows away from the side of the sample, the test shall be cancelled and another sample shall be taken for retest.

④ Calculation of infiltration amount: the infiltration amount is the mass after liquid absorption minus the strip mass, and the result is expressed in G. Infiltration amount (g) = mass after liquid absorption - strip mass. Test 8 samples for each sample, remove the maximum and minimum values of the 8 samples, and take the average value of the remaining 6 samples as the test result, accurate to 0.1g.

⑤ For the test of front transverse diffusion width, after the test solution of the above test penetrates into the sample, measure the front transverse diffusion width of the sample with a steel ruler immediately. If the diffusion width of the inner absorption layer is greater than that of the surface layer (outer cladding), the diffusion width of the inner absorption layer shall be taken as the result. When more than 2 (excluding 2) of the 8 samples have full width, the test result of the sample is determined to be full width. The smaller the width, the better.

Although the penetrability test of thickened sanitary napkins is very cumbersome, such strict requirements can achieve the best quality control, obtain the best products and make users feel at ease.

Comment(0)

You can comment after

SIGN IN