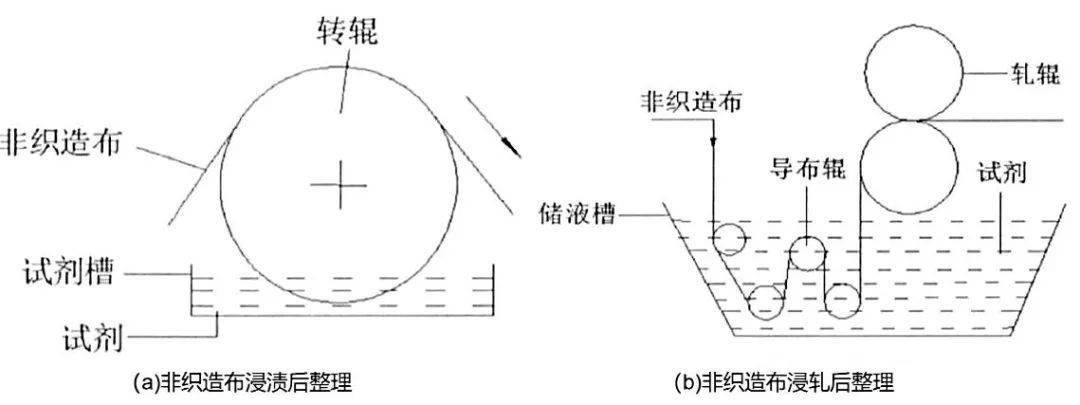

One way to improve the functionality of disposable hygiene products is to give textile materials a whole new function in a simpler way, thus expanding the range of product applications and providing consumers with a better experience of using them. The finishing of disposable hygiene is usually done by impregnation and dipping and rolling, as shown in the figure.

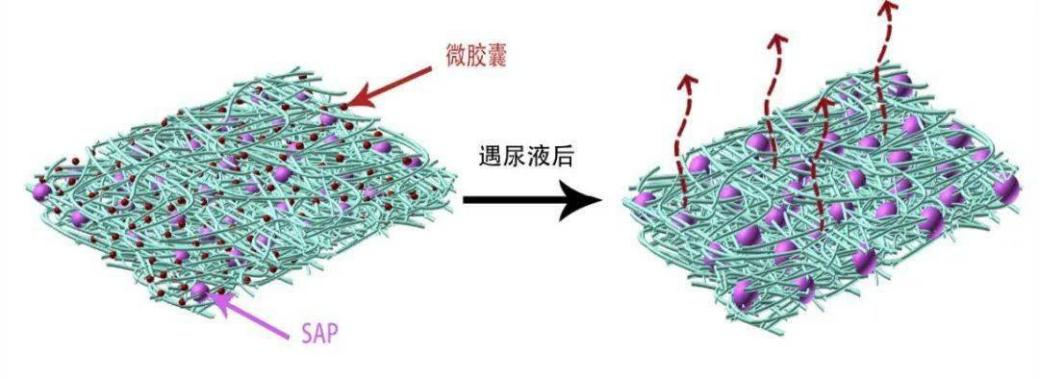

MarianaPohlmanneta with butter and flavor and other lipophilic substances as the core material, the use of microencapsulation technology to synthesize with skin care, sterilization, anti-inflammatory and other methods to prepare the surface of the female sanitary napkin non-woven fabric by the surface of the non-woven spray, impregnation, disinfection treatment, help balance the microflora of the female vulva area, improve the safety of using sanitary products. SibelKaplanetal study found that natural antimicrobial agents can be used. Such as cinnamaldehyde, geraniol and phenylethyl alcohol for antimicrobial finishing, which would only slightly reduce the liquid-absorbent performance of disposable sanitary products, but not reduce other application performance indicators of disposable sanitary products. In addition to the above-mentioned antimicrobial and skin-friendly modifications of disposable sanitary products, moisture-release aromatic microcapsules finishing to absorbent core non-woven materials, when the core meets urine, aromatic microcapsules release fragrance to cover excretion odor, is also a feasible solution.

Comment(0)

You can comment after

SIGN IN