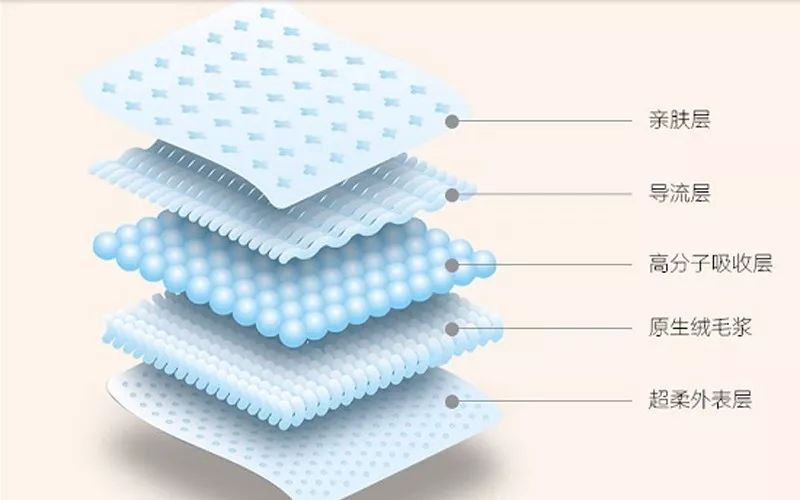

The current research on the structure of nonwoven materials for disposable sanitary products mainly focuses on two aspects: the guide layer and the absorbent core material. The guiding layer between the surface layer of diapers and the absorbent core layer plays the role of accelerating liquid diffusion, penetration and reducing liquid seepage. The fineness, curl, hydrophilic property, spatial arrangement structure of fiber network and fluffiness of the nonwoven fabric of the guiding layer are designed by strengthening type and other methods to make the product performance better. Based on the analysis of the action mechanism of the infusion layer, a composite infusion layer material is designed. Among them, the conventional guide layer and fiber random arrangement of fiber directional arrangement to form a damping layer, conventional guide layer to increase the diffusion of liquid in the fiber network; it has a certain permeability, can prevent the rapid infiltration of liquid, but will not spread in the guide layer. This new structure enables the liquid in the guide layer material to diffuse in the longitudinal direction so that the permeability is balanced. Compared with ordinary hot air cotton with infusion layer, the infusion process can reduce the production cost and the diaper has a higher liquid absorption rate, and its finished product has the advantages of fast liquid absorption rate, long liquid diffusion length and small liquid back seepage.

The absorbent core layer is the core of diaper technology. In order to meet the requirements of consumer comfort, it is necessary to develop in the direction of fine, thin and light while satisfying the requirements of water absorption, so a "sandwich type" absorbent core layer is designed, which consists of four layers of absorbent paper, non-woven fabric, SAP and absorbent paper. Compared with the ordinary SAP / fluffy pulp core layer, the thickness is reduced by 40.95%, and the surface is flat after absorbing water, so that the general diapers do not appear lumpy and bulging phenomenon.

Comment(0)

You can comment after

SIGN IN