Disposable hygiene products are also called "Absorbent Disposable Products", including feminine hygiene products (sanitary napkins, sanitary pads, sanitary plugs), baby diapers, and adult incontinence products (adult diapers, skin care products). Disposable hygiene products were created with the continuous progress of modern society, the rising standard of living and the push of mass production technology. Throughout the 20th century, its birth and rapid development changed the lives of countless women and children, young and old, and influenced the entire course of human civilization.

For more than a decade, China's disposable hygiene products market has developed rapidly, with various products starting from scratch, production levels and consumption levels continuing to improve, and market penetration rates increasing. 2019, in the face of the market environment with increasing levels of risk at home and abroad, China's market is still maintaining an upward trend, with the overall market size growing by 3.4% compared to 2018, reaching about 116.53 billion yuan. As China's population ages, adult incontinence products, a "rising star" in the market, are becoming increasingly accepted as the fastest growing consumer product in the market. In the past five years, China's adult incontinence products compound annual growth rate of 15.5%, female sanitary products and baby diapers / pads compound annual growth rate of 3.1% and 8.8% respectively, which shows that China's adult incontinence products market is facing an excellent development opportunity. At the same time, the domestic market for women's hygiene products and baby diapers/pads will become saturated, and there is still a need to improve the functional added value of the products to meet the requirements of personalization and high quality.

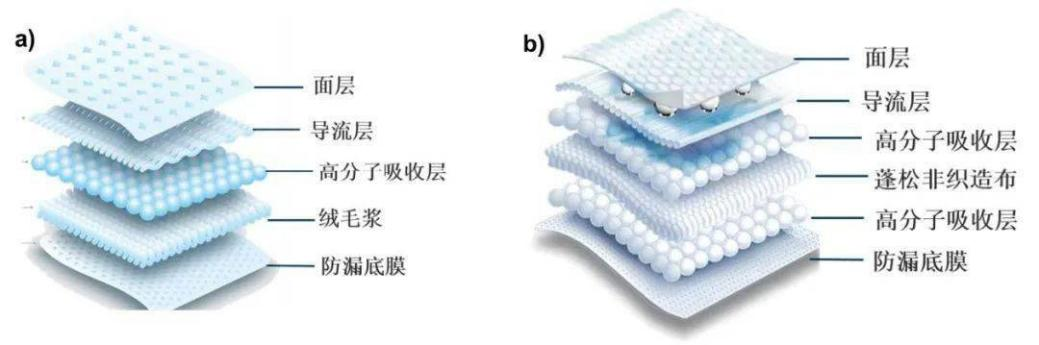

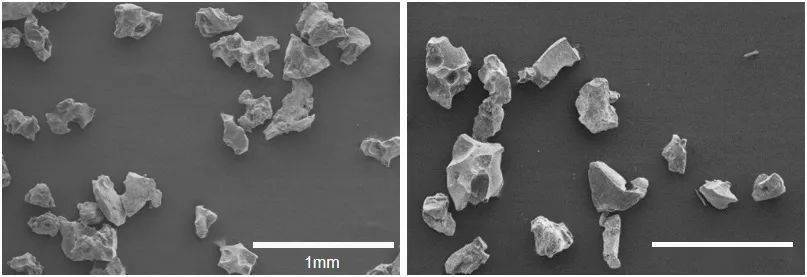

In general, disposable sanitary products include a surface layer, an infusion layer, an absorbent core layer and a bottom layer, as shown in Figure 1. In the inside surface layer, the infusion layer is usually composed of non-woven material. Among them, the absorbent core is the core role layer, which is usually a composite material made of a mixture of fluffy pulp fibers and highly absorbent resin particles (see Figure 2) wrapped with dust-free paper or thin nonwoven material. The fibers used in the above layers of nonwoven materials are mainly polypropylene (PP), polyethylene (PE), and two-component ES fibers, as well as natural or recycled fibers such as cotton and viscose fibers, and thus have greater advantages in terms of cost, health care, and safety. Currently, the commonly used methods for preparing disposable sanitary products are spunbond and hot air meltblown methods. Conventional nonwoven molding process and technology can meet the current needs of some consumers, but in the general health environment, people's living standards continue to improve, and the requirements for functional features and quality continue to increase.

Along with the continuous development of nonwoven technology at home and abroad, disposable hygiene with nonwoven materials continue to update, new products continue to emerge, from the fiber raw materials, production process, appearance and shape to show a variety of innovative achievements to meet the absorbency with the abandonment of the product breathable, rapid absorption of moisture, moisture permeability, anti-reflux and skin contact comfort requirements.

Comment(0)

You can comment after

SIGN IN