Professional hygiene products and personal hygiene products are related to nursing care, and safe hygiene care products must be natural and free of harmful ingredients. The brand name "PURECARES" itself reflects these characteristics. The polyolefin technology used in the company's products is free of phthalates, hydrogen peroxide and tris(nonylbenzene) phosphates, which helps processors produce high-purity nonwoven and hygiene film materials, in accordance with strict hygiene regulations.

Due to different cultural preferences, consumers have different perceptions of comfort and softness, so this must be taken into account when designing and producing areas for hygiene products. For example: In Europe and North America, people consider softness like cotton, with lint and curly fibers. In contrast, most Asians prefer a smooth, silk-like surface. sABIC offers solutions with different touch points, including two-component PP/PE, modified one-component PP and soft-touch one-component PP, depending on the needs of different markets.

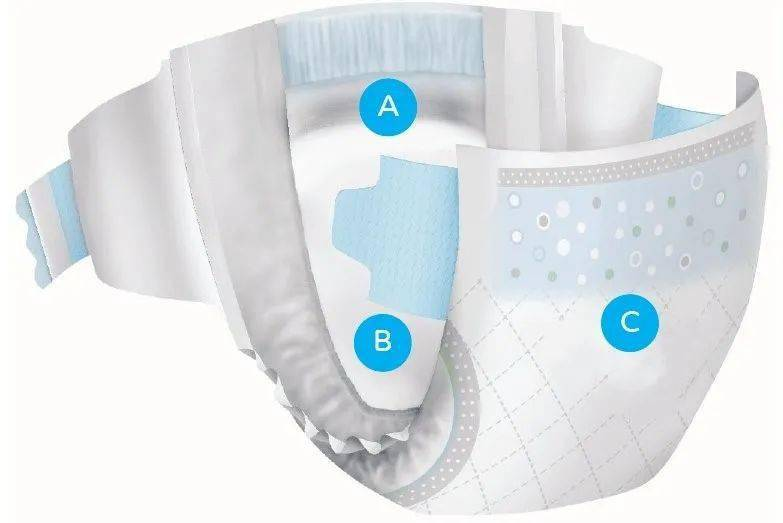

The PURECARES series of PP fiber grades made from lightweight nonwoven fabrics apply Reicofil's latest spunbond meltblown production process. The new PP products with extremely high uniformity of melting, high resistance and breathability make consumers more comfortable. The product is supplied in particulate form, easy to process and store, and shows good processing performance in high speed production. Polyolefins proven in a variety of industries can be used in cast and blow molding processes to produce hygiene rolls and laminated films with desirable base and top layer products such as water tight, breathable and elastic. The diagram below illustrates the application of combining nonwovens and these benefits in baby diapers.

Surface layer (A) and absorbent layer (B) with SMS/SMMS structure, base layer (C) laminated with PE and membrane

* S = spunbond, M = meltblown

Comment(0)

You can comment after

SIGN IN