It is understood that

the car in the scorching sun exposure,

the temperature in the car is generally more than 60 degrees.

For about two hours of exposure,

the maximum temperature in the car will even reach 85℃!

According to our survey,

in order to be able to help baby change diapers anytime and anywhere,

mothers often put diapers in the car for backup,

NO!

High polymer sunburn, affect the absorption of urine!

The chances of red farts in babies will go up!

Today,

We here to talk to moms about

what exactly happens to diapers in high temperatures.

Hot melt glue "melts" in a sultry environment

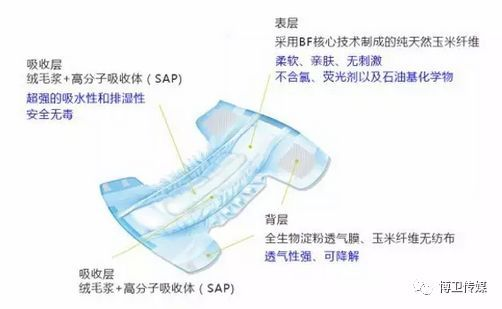

The diaper production process is a relatively complex combination process, the surface layer of non-woven fabric, absorbent core, PE composite bottom film, Velcro, waistband stickers, anti-side-leakage non-woven fabric, rubber band and other materials combined, and through the hot melt glue to combine the above materials, the above is the current production process used by all diapers. It can be seen that "hot melt glue" is basically used in the production process of diapers.

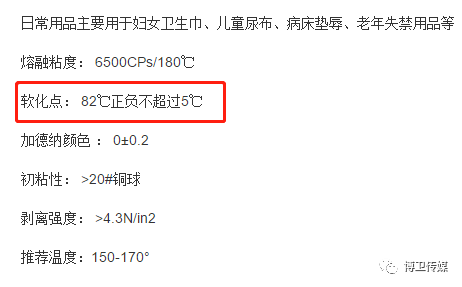

The figure shows that the softening temperature of hot melt adhesive of disposable sanitary products is 82℃, and the positive and negative temperature does not exceed 5℃. Industry insiders point out that: after the car is exposed to the sun and the diaper is in a high temperature environment for a long time, the hot melt adhesive structure prevalent in the diaper is extremely susceptible to oxidation and aging, followed by the phenomenon of shedding and a decrease in strength viscosity, which even leads to a decrease in the quality of the diaper and even quality problems.

The hot melt adhesive used for bonding between layers of diaper materials and on tapes is a structural adhesive (high strength, able to withstand large loads, and resistant to aging, fatigue and corrosion) with stable performance, and can be used as a structural part adhesive that can resist strong bonding, but when it is used as a special adhesive and product demand, it also has a certain pressure sensitivity. Therefore, under long time "high temperature", it will show good "initial adhesion" and the peeling force will be reduced. So, there will be viscose "melting" and rubber band shrinkage. Therefore, diapers should not be left at a temperature above 60℃ for a long time.

SAP "exposure", the baby's chances of red buttocks increased.

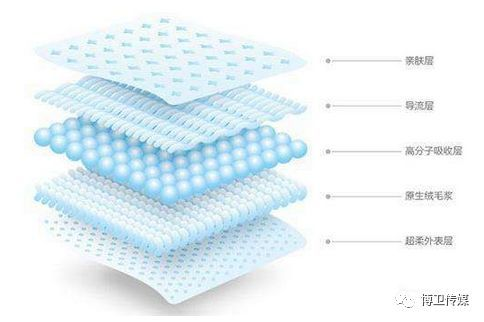

Polymers absorbent (SAP) is a typical functional polymer material. This material can absorb hundreds or even thousands of times its own weight in water and has an extremely strong water retention capacity, so it is also known as a super absorbent or high water retention agent.

SAP is an important part of diapers, and it can be said that the emergence of polymeric absorbents has led to a revolution in the use and production of diapers. It is reported that consumers are particularly concerned about the water-absorbing ability of diapers, while diapers are left at high temperatures for a long time, which likewise seriously affects the performance of SAP and reduces the diaper's ability to absorb urine.

"Polymers contain acidic groups and their performance stops completely when the ambient temperature reaches 80°C." Industry expert Mr. Zhou said. High temperature will also prompt the cross-chain reaction within, so that its absorption multiplier decreases and it is easy to produce antipermeability.

Not only that, because there must be acidity in SAP, the acidic molecules have the ability to maintain PH balance. After the high temperature, the SAP genetic structure is destroyed, then SAP no longer has the ability to PH balance. If the baby uses diapers with higher temperature and the urine is released in a short period of time, the diaper performance is very poor at this time, then the urine will directly irritate the baby's skin, and it will lead to diaper rash, or increased chances of red farts.

Non-woven fabric, PE film aging deterioration.

Various chemical raw materials and products are prone to oxidation and aging under high temperature conditions. Paper diapers are mainly composed of the surface layer, absorbent layer, bottom film and other components, and these components contain chemical raw materials, such as non-woven fabrics, PE film and other components. Relative to the normal room temperature, every 10 degrees higher, the aging rate of the diaper material structure is four times higher than normal.

Non-woven fabrics are affected by high temperatures in the car, the temperature rises, resulting in fabric aging, the performance of diapers will drop significantly, and PE base film also because of high temperatures, its material structure are changed, the proper product performance is lost or reduced, the baby is prone to leakage.

Therefore,

mothers should never put diapers on the car for the sake of convenience,

resulting in unnecessary injuries to the baby!!!

Comment(0)

You can comment after

SIGN IN