The SABIC special topic report that the global population is expected to reach 9.7 billion and continues to grow and toward aging. Therefore, human reliance on individual and medical health products produced by plastic non-woven fabrics will be further increased, and it cannot longer meet this demand with limited fossil resources.

To meet this challenge, Saudi Basic Industries (SABIC) has launched the TRUCIRCLE™ project and launched new materials for certified recyclable and renewable polymers in the non-woven dedicated PURECARES™ polyolefin series product platform. In the future, plastic waste will also be a part of environmental solutions.

Photo source: SABIC

Driven by major global trends, the health products industry is looking for brand new solutions that contribute to product sustainability, safety, and cost-effectiveness while bringing convenience and functionality to consumers.In 2020, the market for personal hygiene products has exceeded US $100 billion, up 7% year on year.

Whether it is baby care supplies, sanitary napkins, adult diapers, or disposable medical supplies and surgical clothing, non-woven fabrics are widely used, and can determine the performance and purity of the product according to different material choices.In addition, non-woven materials also need to follow strict safety regulations, and brand owners and processors face fierce competition in the global market, so cost control is also one of the important factors that they consider.

SABIC is committed to working with value chain partners on these trends and challenges to contribute to industry innovation and common prosperity by constantly improving product quality and performance standards and developing new materials and process solutions.As one of the first initiatives, the company has developed the PURECARES™ polypropylene (PP) and polyethylene (PE) series of polymers for non-woven fabric and sanitary film applications.

Both personal hygiene and professional hygiene products are related to care, while safe health care products need to be very pure without any harmful ingredients.The brand name "PURECARES" itself highlights these characteristics.The series uses polyolefin technology without phthalates, peroxide and three (nylphenyl) phosphate, complies with strict hygiene regulations and can help the processing plant produce high purity non-woven and sanitary film materials.

The comfort and softness experienced by the consumer vary by cultural preferences, so this must be taken into account when designing and producing sanitary products for different regions.For example, in Europe and North America, softness is regarded as a cotton feeling, with fluffy and curly fiber.

In contrast, most Asians prefer silky, smooth surfaces.SABIC provides different tactile solutions for different market needs, including leather core structure two-component PP / PE, modified single component PP, and soft touch single component PP.

The PURECARES series PP fiber brand products for lightweight non-woven fabrics can be applied to the latest Reicofil spinning and melt-injection production processes 3. The new PP products with ultra-high melt fluidity bring a high degree of fiber uniformity, high barrier and air permeability, thus improving consumer comfort.It is supplied in granular form for easy processing and storage, and shows good processing performance on high-speed production lines.

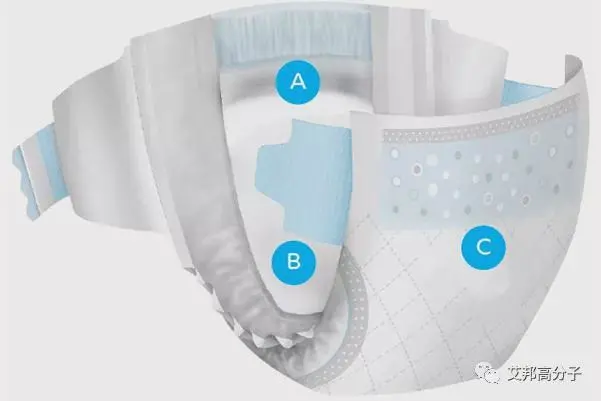

A variety of industry-proven polyolefins should be used for flow extension and blow molding processes to produce sanitary rolls and composite films, and to provide the ideal bottom and top layer, such as water tightness, air permeability and elasticity.Figure 1 shows the application of typical non-woven structures combining these advantages in infant diapers.

Figure 1 Case of S A B I C ® PP non-woven fabric application

Surface layer (A) and absorption layer (B) with SMS / SMMS structure, bottom layer (C) composite with PE, membrane * S = spinning adhesion, M = melt spray.(Source: SABIC)

In addition to strong functionality, comfort, efficient processing, and compliance, innovation in non-woven products must also meet the growing requirements for environmental compatibility and sustainability.This requires the development of innovative solutions that can solve the plastic waste problem, and to support the transformation of the plastic industry from a linear economy to a circular economy.

Plastic waste is seen as one of the biggest challenges in endangering the Earth's environment. In fact, the many advantages of plastic over other materials cannot be ignored, and promoting advanced solutions for recycling and recycling of plastic waste can minimize and effectively manage plastic waste to achieve economic returns.

Plastic has the advantages of light, hard, soft, pure, safe, high cost-effective and aesthetic, so it is a pity to be abandoned for a single application alone.Moreover, in a highly circular economy, plastics can even make a significant contribution to curbing climate change by reducing greenhouse gas emissions.

Two years ago, SABIC launched the TRUCIRCLE™ project, designed to transform the industry, develop and launch more sustainable applications through innovative materials and services.

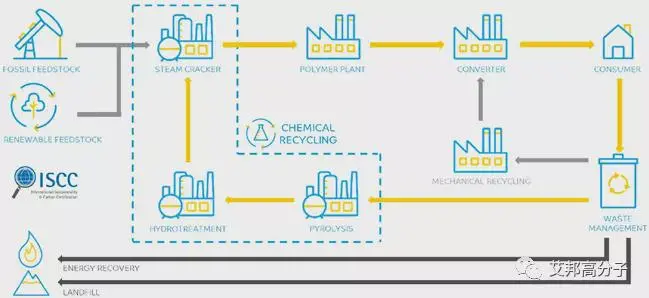

The project is based on two pillars: First, to help reduce fossil energy consumption and minimize waste by launching a range of physical recycling, certified recycling and renewable products. At the same time, the company has also launched many services to support circular product design and measures conducive to the closed-loop economy.

The certified polymer materials in this series are based on a quality balance accounting system and meet the widely recognized International Sustainability and Carbon Certification Program (ISCC PLUS) requirements. Mass balance calculations track the flow of materials from raw materials to terminal applications in a complex supply chain by following pre-set transparency rules.

It enables traceability of all parties throughout the supply chain and enables brand owners to advertise and quantify the sustainable benefits of the final product made from these materials. Figure 2 illustrates the important role of mass balance in driving the circular economy.

Facing global trends and major challenges such as increasing population growth, global warming and plastic waste, the non-woven industry is in urgent need of innovative material solutions to break the limits in quality, efficiency and performance and meet the increasingly stringent requirements for product sustainability.Industries in the industry chain have worked closely to allow complex plastic waste (including non-woven sanitary supplies) to be effectively recycled and make contributions to the development of the circular economy.

Comment(0)

You can comment after

SIGN IN