Purocel EcoDry is a biodegradable and compost adhesive fiber with engineered hydrophobicity designed for Sustainable Absorptive Hygiene Products (AHP). It helps to manufacture ultra-soft non-woven fabrics for AHP top sheet applications, such as sanitary napkins, which keep the user's skin dry while allowing fluid transfer to the core of the AHP. This fiber is completely sustainable in nature, making it possible for the production of environmentally hygienic products that meet the desired performance.

Gladhesive short fibers are essentially a hydrophilic fiber.Our innovative Purocel EcoDry is a special adhesive short fiber, carefully designed with optimally hydrophobicity, obtaining the desired properties in top sheet applications of AHP, such as sanitary napkins or panty liners.Purocel EcoDry fibers provide a perfect balance between the two most critical properties (such as absorption rate, e. g. wetting or wetting) required for absorptive sanitary products.

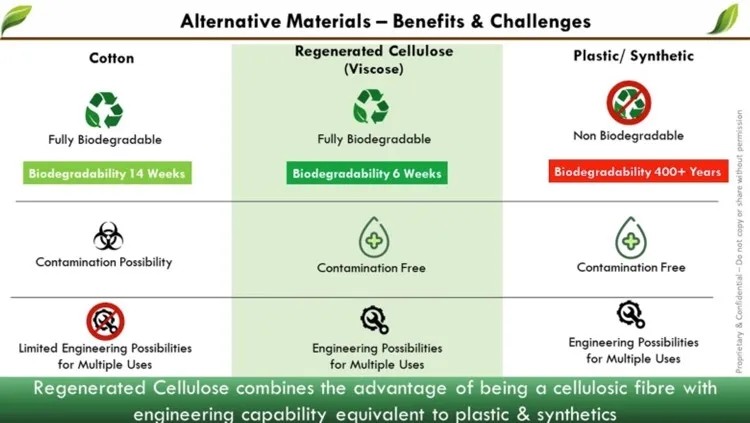

The Purocel EcoDry adhesive fibers perfectly combine the biodegradability and compost properties of natural fibers and the properties of synthetic plastic / oil-based fibers, as shown below.

Viscose fibers for absorbent hygiene products (AHP) are superior to plastic/synthetic fibers and cotton

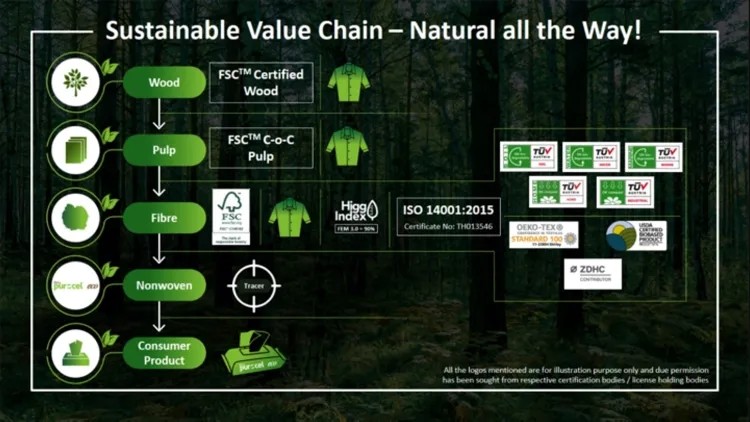

Purocel eco is used to build traceable sustainable products:

Purocel Eco, an ecologically enhanced viscose fiber with built-in molecular tracer, which can achieve 100% transparency. End consumers can now track the source and journey of end products such as wipes through simple QR code scanning, so they can be sure that the source of products is sustainable.

Purocel eco is the first product in the world to provide such functions in the non-woven industry. It injects a unique proprietary tracer that can be identified at any stage of the nonwoven value chain, such as fiber, fabric or final product.

In addition to traceability, Purocel Eco offers a range of sustainability certificates as follows:

Purocel Eco originates from FSC ® certified sustainable forests, thereby protecting biodiversity, saving endangered forests and increasing overall greening coverage

Purocel Eco is produced in EU BAT-compliant manufacturing plant meetings and meets the most stringent European viscose fiber emission standards

As of 2019, purocel Eco's manufacturing plant has a first-class higg FEM (3.0) index of 93%

Purocel Eco is committed to reducing greenhouse gas emissions by 65%, reducing water emissions by 75%, using more than 50% renewable energy and following a closed-loop production process where more than 90% of the sulfur is recovered and recycled, making it more sustainable

Note: compared with ordinary viscose fiber

Purocel Plus Fibers for 100% Viscose-Based Wipes:

Specialized fibers for sustainable cellulose wipes - compliant with the EU Single-Use Plastics Directive

Special viscose fiber that transforms from a plastic fiber to a sustainable 100% cellulose fiber while maintaining good processability and wiping properties.

EU supd compliant

Fully biodegradable and compostable (certified by TUV Austria)

Enhanced processing capability

Improved wiping performance

Comment(0)

You can comment after

SIGN IN